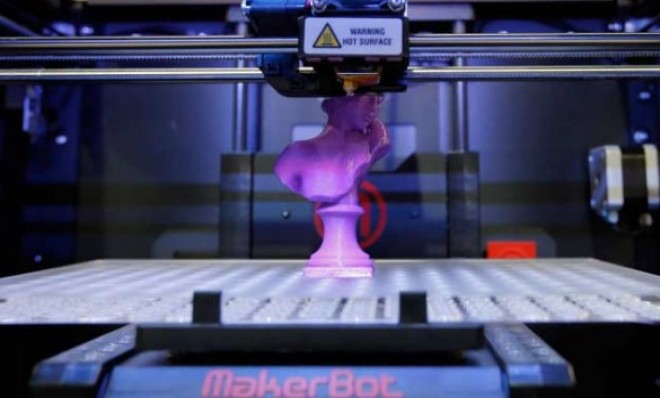

How 3D printers might help us build a base on the moon

Mankind's quest to live among the stars gets a little more realistic with the advent of 3D printing

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

You are now subscribed

Your newsletter sign-up was successful

If humanity's longtime dream of a moon colony is ever going to be achieved, its architects will have to deal with the fundamental logistical problem of having to haul boatloads of building materials into outer space — an expensive and time-consuming endeavor that, quite simply, isn't feasible considering the financial troubles NASA is currently facing.

So... what then? The answer, say skyward-looking engineers, is to harvest available materials from the moon itself. The European Space Agency recently revealed plans to use a 3D printer to build the complex shapes and pieces of equipment that would make up an inhabitable space base.

3D printing, lest you forget, is a technique that allows users to "print" three-dimensional objects layer-by-layer. Usually, the printers employ plastic in place of ink, but a diverse range of materials like metal, clay, and yes, even chocolate can be used to print toys, furniture, or whatever else can be sketched out with AutoCAD, software for computer-assisted design and drafting. More recently, 3D printers have been the subject of intense scrutiny, with several media outlets reporting that people can theoretically build operational handguns and rifles at home if they download the correct plans.

The Week

Escape your echo chamber. Get the facts behind the news, plus analysis from multiple perspectives.

Sign up for The Week's Free Newsletters

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

Now, a team of researchers from the architecture firm Foster + Partners is exploring the possibility of using portable 3D printers to convert lunar material into a moon base. Working with a UK-based company called Monolite, researchers were able to chemically mold sand-like material together with a special kind of binding salt that forms into a sturdy, stone-hard solid. "Our current printer builds at a rate of around 2 m per hour," Monolite founder Enrico Dini tells Discovery News, "while our next-generation design should attain 3.5 m per hour, completing an entire building in a week." (Take a look at the base and the machine here.)

This, however, isn't the first time 3D printing has been tapped to possibly build a moon base. Last year, NASA challenged researchers at Washington State University to develop a technique to build smooth, cylindrical shapes for a future space habitat.

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

-

What are the best investments for beginners?

What are the best investments for beginners?The Explainer Stocks and ETFs and bonds, oh my

-

What to know before filing your own taxes for the first time

What to know before filing your own taxes for the first timethe explainer Tackle this financial milestone with confidence

-

The biggest box office flops of the 21st century

The biggest box office flops of the 21st centuryin depth Unnecessary remakes and turgid, expensive CGI-fests highlight this list of these most notorious box-office losers