How to use chemistry to age whiskey in days instead of years

A Cleveland-based start-up is condensing the process to about a week

Maker's Mark attracted gobs of unwanted (or perhaps pre-meditated?) attention earlier this year when it announced that it would begin watering down its bourbon in order to meet the market's unprecedented demand.

A swift and severe public butt-kicking kept Maker's from following through, but the company's decision to dilute its alcohol content was apparently the result of basic supply-and-demand economics. Maker's shipped 16.9 million cases of Kentucky and Tennessee whiskey in 2012, which was up 14.9 million cases from 2007. (Which just so happens to be the year Mad Men made its debut. Hmmm.) Decent bourbon, however, takes at least eight to 10 years to reach maturity. Maker's Mark simply failed to make enough of bourbon to anticipate its soaring popularity.

But what if the aging process could be condensed using some technical wizardry? That's what's driving a new bourbon-maker called Cleveland Whiskey. Based out of its namesake city, the company's premise is to synthetically age alcohol at a much faster pace using a controlled chemical process. Instead of taking years, Cleveland Whiskey is aged to maturity in just about a week.

The Week

Escape your echo chamber. Get the facts behind the news, plus analysis from multiple perspectives.

Sign up for The Week's Free Newsletters

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

Founded by former marketing executive Tom Lix, Cleveland Whiskey has basically been an overnight success. Since March 1, the company has sold more than 14,000 bottles, which works out to about 1,000 bottles week — not bad for a small-batch brewer. Lix says he plans on producing 7,000 cases of Cleveland Whiskey this year, before ratcheting things up to 20,000 cases in 2014.

The process involves highly pressurized vats, along with pieces of charred oak to infuse the bourbon with its signature character. "I took apart a couple of used barrels, and it didn't seem like the whiskey soaked very deep," Lix told Forbes. "So I started experimenting with pressure to get the spirit to soak deeper into pore structure."

The spirit ages in a whiskey barrel like normal for the first six months of its life. Then it is deposited in stainless steel tanks. Meanwhile, the barrel it aged in is cut up, processed, and put into the tank as well. Within the tank, the spirit is agitated, and undergoes a series of differences in pressure to squeeze in and out of the wood pores. "Like a sponge," Lix said. Once deposited in the tank, the whiskey takes about a week to create. [Forbes]

The important question, of course, is what does the stuff actually tastes like? "Not bad" seems to be the consensus, although one blind taste-tester told Forbes that it tasted more like "an Irish whiskey than it did a bourbon."

Cleveland Magazine was more effusive with its praise:

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

It's dark in the bottle, a gorgeous honey-amber hue in a glass. The aroma was rich and complex. It had none of the bite or harsh alcoholic "heat" — though it is 100 proof — that usually comes with young (and therefore inexpensive) whiskey. The mouthfeel is round and silky. An added splash of water smooths it out even more. This is comparable to a very fine high end bourbon. And it will sell for a fraction of the price. [Cleveland Magazine]

With a patent pending, Lix is careful not to divulge too many specifics about the process. But he is optimistic about his chances of disrupting an industry that has more or less abided by the same basic tenets for centuries. "I believe in the Coca-Cola model," he told Cleveland.com. "Don't tell anybody anything."

-

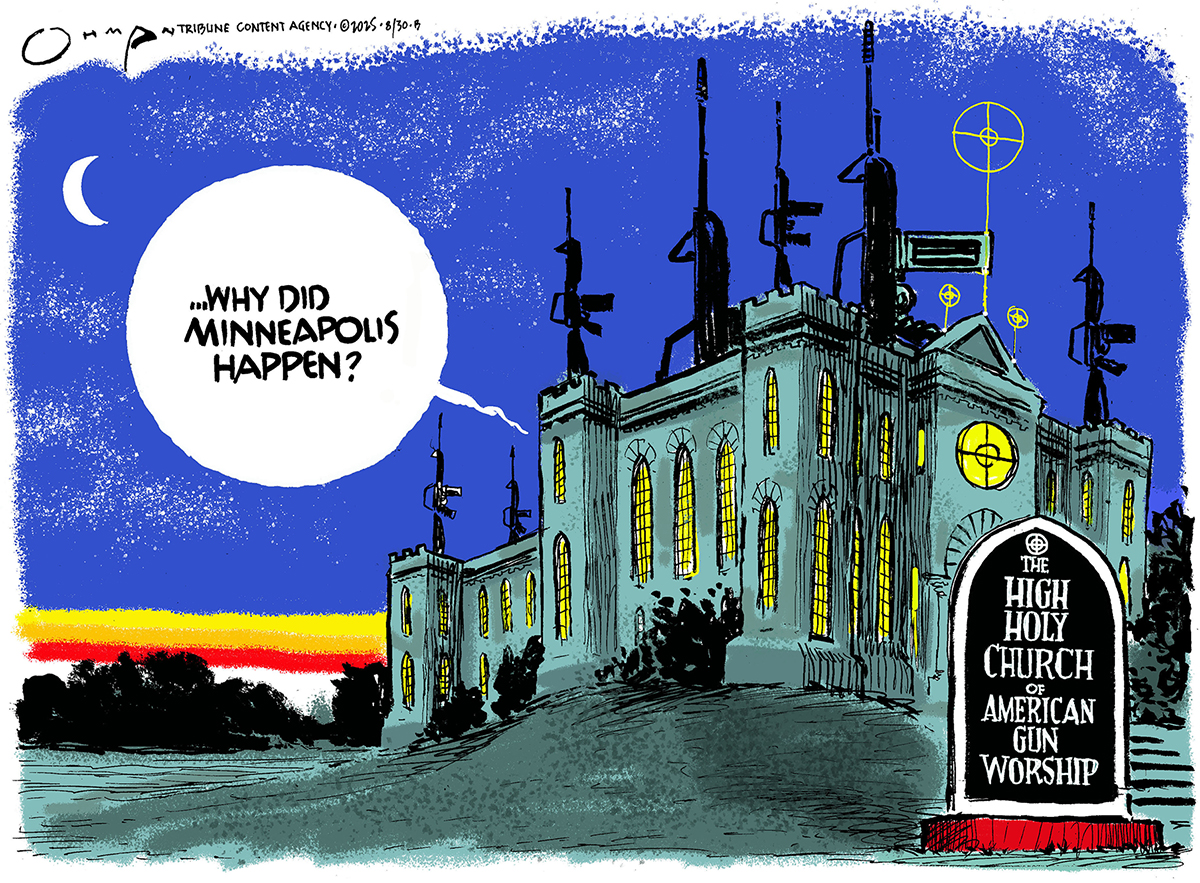

5 bullseye cartoons about the reasons for mass shootings

5 bullseye cartoons about the reasons for mass shootingsCartoons Artists take on gun worship, a price paid, and more

-

Lisa Cook and Trump's battle for control the US Fed

Lisa Cook and Trump's battle for control the US FedTalking Point The president's attempts to fire one of the Federal Reserve's seven governor is represents 'a stunning escalation' of his attacks on the US central bank

-

'Three Pads' Rayner: a housing hypocrite?

'Three Pads' Rayner: a housing hypocrite?Talking Point As real estate moguls go, the Deputy PM is 'hardly Donald Trump'