British team creates microscopic 3D printing technique

Tiny component could be used to create nano-computers of future

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

You are now subscribed

Your newsletter sign-up was successful

A British team has pioneered the use of 3D printing on a microscopic level, using the technique to create a new composite material which could be used to store data – and accelerate moves towards nano-computing.

The project is a collaboration between the engineering and chemistry departments of Nottingham University, led by Victor Sans Sangorrin and Graham Newton, who published their results in a scientific journal last month.

They created their tiny component by combining a rigid plastic polymer with photochromic molecules, which change colour when exposed to light.

The Week

Escape your echo chamber. Get the facts behind the news, plus analysis from multiple perspectives.

Sign up for The Week's Free Newsletters

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

“This approach could be used to develop materials for energy storage and electronics,” Newton said. “In theory, it would be possible to reversibly encode something quite complex like a QR code or a barcode, and then wipe the material clean, almost like cleaning a whiteboard with an eraser.”

Their innovation is the latest in a field poised to revolutionise manufacturing.

A decade ago, 3D printing was a buzz-phrase, but the technique has so far failed to deliver on its promise. Don’t be fooled, says Wired – the latest innovations in the technique mean the promised revolution is coming “for real this time”.

Ric Fulop, chief executive of Desktop Metal in Massachusetts, told the magazine, “During first 20 years of 3D printing, the technology was too slow and expensive, so its primary use was prototyping. Today, 3D printing is finally starting to be used for high-volume, mass production.”

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

The latest innovation represents the “digitisation of metal fabrication”, says the magazine. It matters because of the hugely increased flexibility it offers factories. Instead of having to modify an entire production line to create a new component, companies using the new system would be able to change designs instantly.

Find out how Barclays Corporate Banking’s industry experts are supporting clients to achieve their ambitions at barclayscorporate.com

Take our survey for your chance to win £100 John Lewis vouchers

-

6 exquisite homes with vast acreage

6 exquisite homes with vast acreageFeature Featuring an off-the-grid contemporary home in New Mexico and lakefront farmhouse in Massachusetts

-

Film reviews: ‘Wuthering Heights,’ ‘Good Luck, Have Fun, Don’t Die,’ and ‘Sirat’

Film reviews: ‘Wuthering Heights,’ ‘Good Luck, Have Fun, Don’t Die,’ and ‘Sirat’Feature An inconvenient love torments a would-be couple, a gonzo time traveler seeks to save humanity from AI, and a father’s desperate search goes deeply sideways

-

Political cartoons for February 16

Political cartoons for February 16Cartoons Monday’s political cartoons include President's Day, a valentine from the Epstein files, and more

-

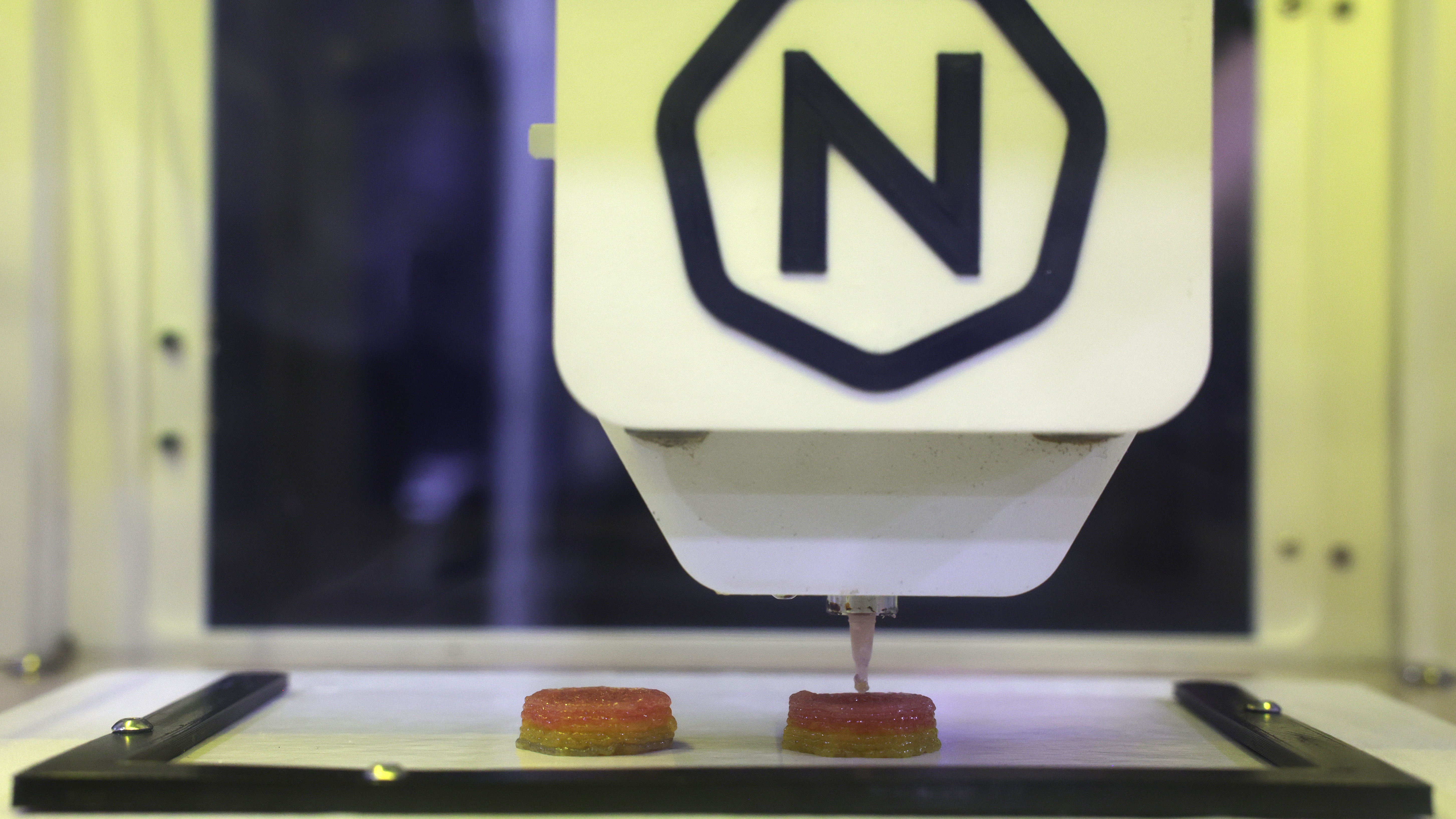

The 3D printing food revolution

The 3D printing food revolutionfeature Technology has the potential not only to boost nutrition but help ease food insecurity on a global scale

-

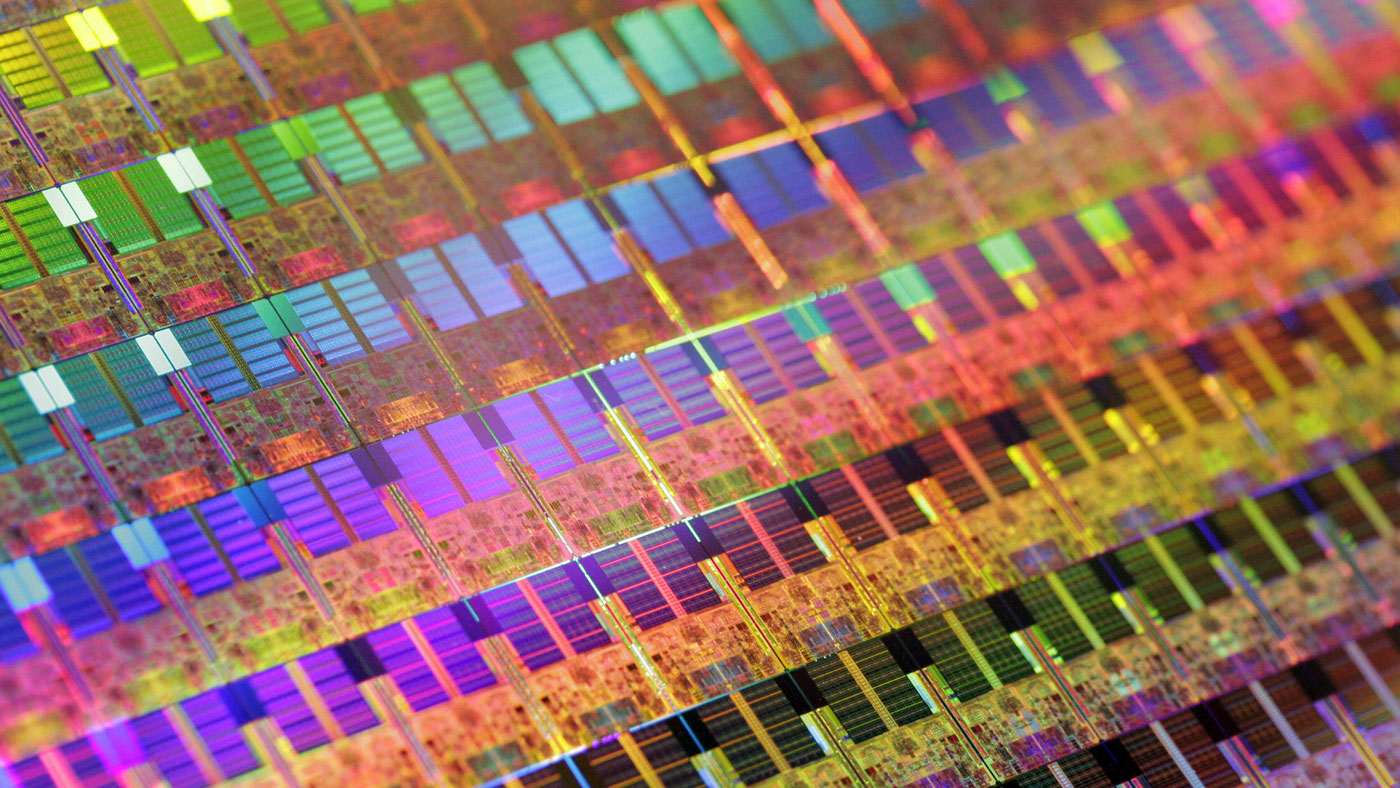

How cybercriminals are hacking into the heart of the US economy

How cybercriminals are hacking into the heart of the US economySpeed Read Ransomware attacks have become a global epidemic, with more than $18.6bn paid in ransoms in 2020

-

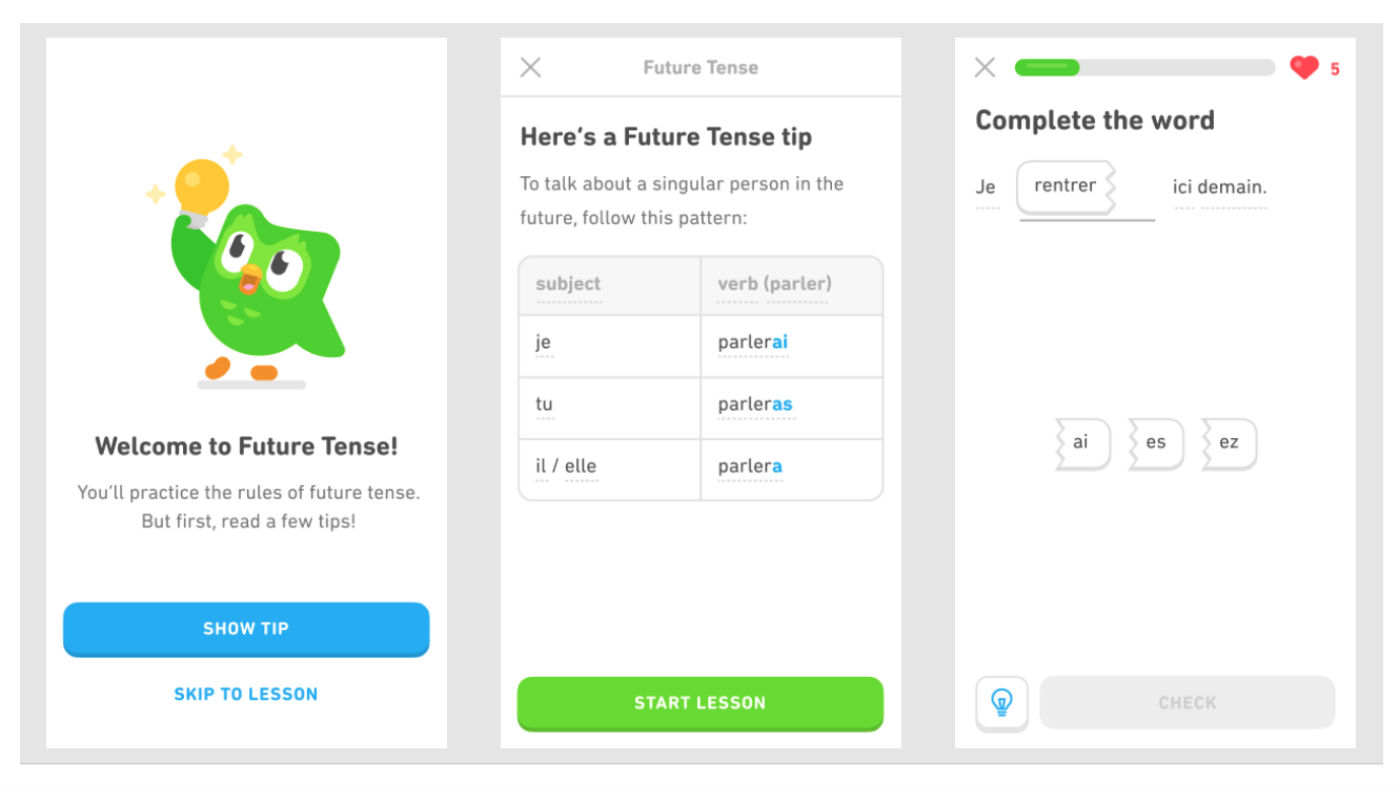

Language-learning apps speak the right lingo for UK subscribers

Language-learning apps speak the right lingo for UK subscribersSpeed Read Locked-down Brits turn to online lessons as a new hobby and way to upskill

-

Brexit-hobbled Britain ‘still tech powerhouse of Europe’

Brexit-hobbled Britain ‘still tech powerhouse of Europe’Speed Read New research shows that UK start-ups have won more funding than France and Germany combined over past year

-

Playing Cupid during Covid: Tinder reveals Britain’s top chat-up lines of the year

Playing Cupid during Covid: Tinder reveals Britain’s top chat-up lines of the yearSpeed Read Prince Harry, Meghan Markle and Dominic Cummings among most talked-about celebs on the dating app

-

Brits sending one less email a day would cut carbon emissions by 16,000 tonnes

Brits sending one less email a day would cut carbon emissions by 16,000 tonnesSpeed Read UK research suggests unnecessary online chatter increases climate change

-

Reach for the Moon: Nokia and Nasa to build 4G lunar network

Reach for the Moon: Nokia and Nasa to build 4G lunar networkSpeed Read Deal is part of the US space agency’s plan to establish human settlements on the lunar surface

-

iPhone 12 launch: what we learned from the Apple ‘Hi, Speed’ event

iPhone 12 launch: what we learned from the Apple ‘Hi, Speed’ eventSpeed Read Tech giant unveils new 5G smartphone line-up