The 3D printing food revolution

Technology has the potential not only to boost nutrition but help ease food insecurity on a global scale

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

You are now subscribed

Your newsletter sign-up was successful

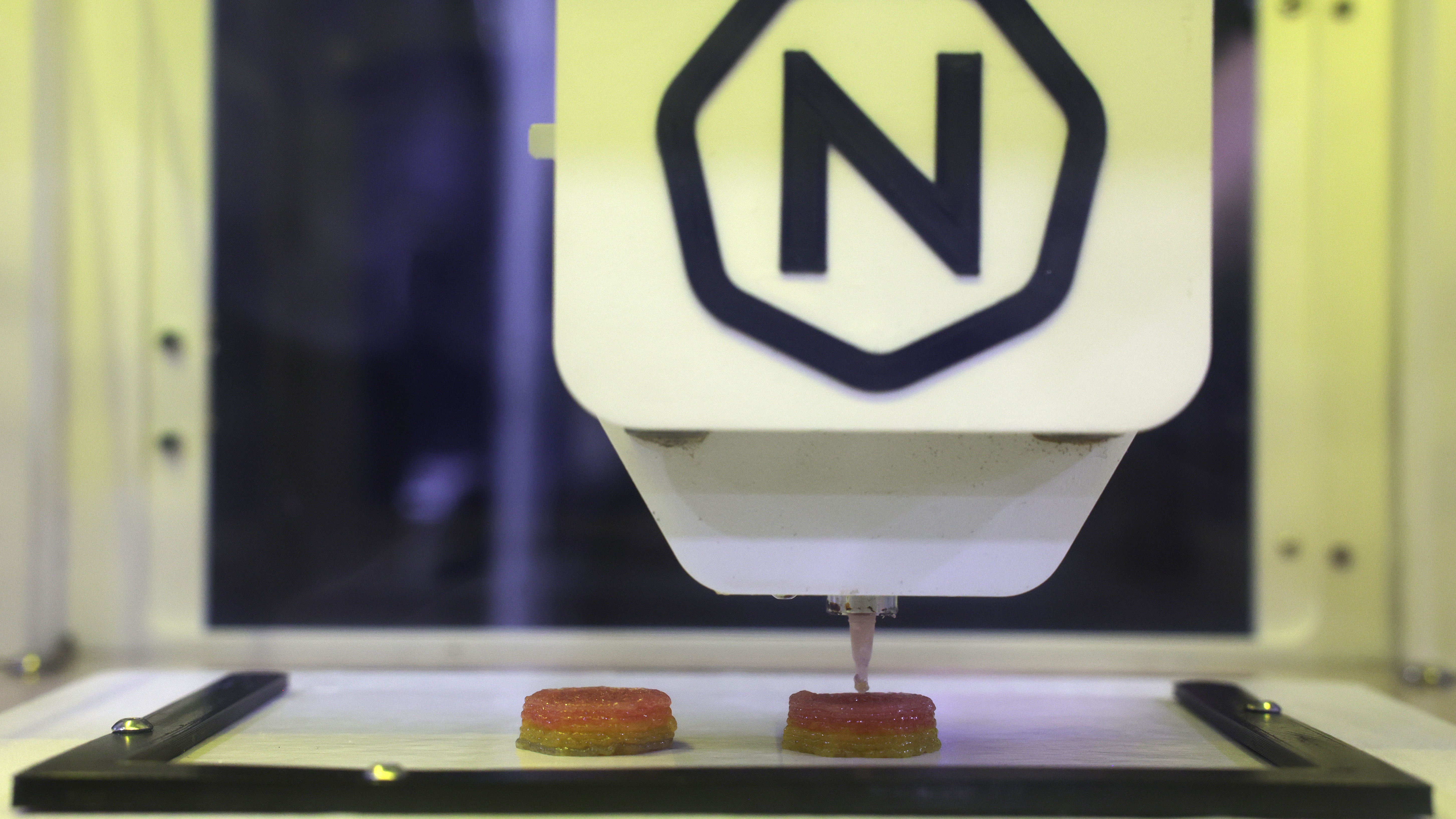

Your kitchen could have its own “personal digital chef” one day, say researchers – that’s if they can perfect the technology behind the world’s first 3D printed cheesecake.

Last week, a team of engineers at Columbia University in New York used an array of “edible food ‘ink’” to print the dessert. It took them 30 minutes and they used crackers, peanut butter, chocolate spread, banana puree, strawberry jam, cherry juice and icing, said the BBC’s Newsround.

All ingredients were mashed into paste and the printer was combined with a laser to cook the food. Once the various items were printed, cooked and layered together “it tasted like something I hadn’t tried before”, said Jonathan Blutinger, an engineer at the university’s Creative Machines Lab. But “I rather enjoyed it”, he added.

The Week

Escape your echo chamber. Get the facts behind the news, plus analysis from multiple perspectives.

Sign up for The Week's Free Newsletters

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

This reimagining of an American classic dessert is “the best thing we can showcase right now” when it comes to 3D food printing, said Blutinger. But it is also possible to print chicken, beef, vegetables, cheese – “anything that can be turned into a paste, liquid or powder”, he said.

“The vision is to have a food printer mixed with a laser cooker that can be a one-stop-shop sort of kitchen appliance. It’s your own personal digital chef,” said Blutinger.

How does it work?

It took the research team five failed attempts to make their version of the cheesecake.

The ingredients had to be converted into a paste to be properly squeezed through the machine’s syringes and form the necessary layers, said the Smithsonian Magazine. Then, for the final step, the team used a blue laser to brown the top layer of the cake. The whole process took around 30 minutes.

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

This is an “important development”, Kyle von Hasseln, CEO of Sugar Lab, told CNN, as it allows for the transition from a paste to a solid, and therefore offers more control over temperatures and ingredients.

What are the benefits?

The process of printing food like cheesecake allows those with specific diets or certain allergies to be precise with what goes into the food, including calories, fat and sugar, Blutinger told CNN.

It can also make food consumption easier for those with dysphagia – a condition that means people find it hard to swallow.

Beyond that it also reduces the contact humans have with food, which has the potential to stop the spread of food-borne illnesses, said CBS News.

A new UN report outlined the effects of climate change, which has put millions of people in acute food insecurity. 3D printed food is one of the potential “untapped solutions” to that problem, said Axios.

Printed food could also provide people without access to fresh food the essential nutrients that they need and wouldn’t have been able to afford otherwise.

Does 3D food have a future?

While the experiment was a step towards developing practical uses for 3D printing in mechanically assembled food, mass adoption of 3D food printers in everyday life is at least several years away, Blutinger told Axios.

The cheesecake experiment was possible because the machine used was already at Columbia’s New York laboratory, but they are not common in homes and, perhaps most importantly, “there are not yet troves of cookbooks out there spelling out how the tech can be applied”, said CNN.

“If this [technology] were to hit the market, it’s like having an iPod without any MP3 files,” said Blutinger. “So there needs to be a place where you can download recipes, create your own recipes, and get some inspiration for what you can actually do with this machine in order for it to really take off in a big way.”

In the next five years “you’re going to start to see this technology” in many different areas, Blutinger said. He believes that 3D food printers will become commercially viable as the price point continues to decrease.

London’s German Gymnasium restaurant currently serves a 3D-printed plant-based flank steak, described as having a “reassuringly chewy texture” by Sophie Morris in a review for the i news site.