L is for Jonathan Anderson's Loewe

A rare visit to Loewe's legendary leather factory in Getafe, Spain

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

You are now subscribed

Your newsletter sign-up was successful

In September 2013, LVMH entrusted Jonathan Anderson with rejuvenating Loewe, a brand the luxury conglomerate acquired in 1996.

Loewe, Spain’s oldest luxury house, was established in 1846 when a group of Madrid-based leather craftsmen joined forces. It takes its name from German entrepreneur Enrique Loewe Roessberg, who took charge of the guild in 1872 and channelled their combined expertise into building a brand which still thrives to this day.

Following his appointment, Anderson went into bunker mode to map his custodianship of the brand. After an unprecedented 12-month incubation period, during which no new products were introduced, the creative director unveiled his Loewe in June 2014. Mindful of its legacy, while fostering modern design and innovation, he chose artisanal expertise as the house’s lodestar.

The Week

Escape your echo chamber. Get the facts behind the news, plus analysis from multiple perspectives.

Sign up for The Week's Free Newsletters

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

Since his SS15 debut, Anderson has worked with photographers to chronicle his seasonal Loewe men’s and womenswear collections in hardcover-bound books. Produced in a limited limited run of just 1200 copies worldwide, the publications place the house's creations in escapist settings: photographer Jamie Hawksworth imagined Loewe's SS17 collection as the ultra-luxe habiliment of two male friends castaway on a rowing boat in the middle of the Mediterranean Sea. The book follows their journey to Ibiza, the Balearic island being one of Anderson's favourite leitmotifs.

This autumn, Anderson has partnered with American photographer Duane Michals, reputed for his narrative sequences: photographs with hand written annotations that tell a story. For Loewe, Michals cast English actor Josh O'Connor in the role of fictional magician François Faux Pas and joined him with model Erik Frey, dressed in Loewe duffle coats and jacquard-weave jumpers. As his surname suggests, Faux Pas embarks on several clumsily-executed magic tricks: in front of Michals' lens, a 'Flying Chair' is held high by an ill-concealed assistant, his 'Floating Beauty' – a model perched on a chair – fails to levitate.

Magic abounds at Loewe's production site in the city of Getafe, a 30-minute car journey south of Madrid's city centre. The workshop is the centre of Loewe's leather production; in 2012, its surface area doubled to spread across 11,500 square metres, which includes a 2,000-square metre warehouse where raw materials arrive from Spain, France and Italy.

Today, the site is home to 300 Loewe employees, including 150 expert artisans and two in-house leather experts who are in charge of the leather innovation centre: a kind of leather library complete with roughly 3,000 samples. In addition to an archive facility, which contains every material the brand has used, the centre is a hub for artisanal experimentation and research.

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

At the leather innovation centre, Loewe's magic trick is the art of transformation: nothing is quite what it appears to be, as artisans work leathers in ever more fantastical ways.

Goat-leathers masquerade as metallic foils: hides are overlaid with a thin red-coloured aluminium film which is then crackled by hand and washed. Calf-skins are painted by hand to resemble the slick green bark of bamboo plants or printed, stamped and then washed to obtain the look and feel of tie-dyed silk.

“Loewe was a relatively unknown brand to me but when I first visited, I was astounded by their body of work and how it has evolved over its 170-year history,” says Anderson who is one of the youngest creative directors to helm a heritage brand at only 34.

“Leather is such an incredible and versatile material. It’s skin after all, so to be able to draw on the accumulated knowledge and wisdom of our leather artisans when we are creating new designs is a tremendous advantage.”

Today, the designer splits his time between the Loewe ateliers in Paris and the East London headquarters of J.W Anderson, the eponymous brand he launched in 2008. Once a month, Anderson visits Loewe's Madrid sites.

In Getafe, signs of Anderson's five-year tenure – a period marked by a pronounced shift towards the artistic - are in strong evidence: large prints of the brand's current campaigns shot by photographer Steven Meisel lead the way to the site's canteen, which is airy with white-washed walls and contemporary pale wood furniture.

In the leather research centre, archived samples collect Anderson's work so far; his modern interpretation of time-honoured techniques includes Cordovan embossing which originated in the South of Spain and requires wetted leather to be worked by hand.

Anderson's influence is prevalent throughout: earlier this year, Loewe presented the designer's first range of sunglasses– three styles made with expert venture Thélios – at the workshop, an artisan used adhesive stickers printed with the campaign's images showing shades atop a classical marble bust to personalise his toolkit.

The team's uniform includes white cotton lab coats with beige piping and the Loewe's logo or 'Anagram' as the brand prefers to call it- embroidered in dark thread. The emblem was first designed in the 1970s by Spanish artist Vicente Vela, who looked to cattle-branding irons (another connection to leather) for inspiration. It's shape, a quartet of swirling Ls, has given rise to its Spanish nickname of 'El Cangrejo' (the crab).

Anderson's uniqueness lies in his ability to nimbly combine contemporary art practises with existing traditions and timeworn craftsmanship. One of the designer's first initiatives when he joined the house was to overhaul the famous Anagram with the help of graphic designers Mathias Augustyniak and Michal Amzalag of agency M/M Paris. A new simplified graphic was created along with an updated brand name logo inspired by the distinctive Pegasus typeface, conceived in 1937 by German illustrator and typographer Berthold Wolpe.

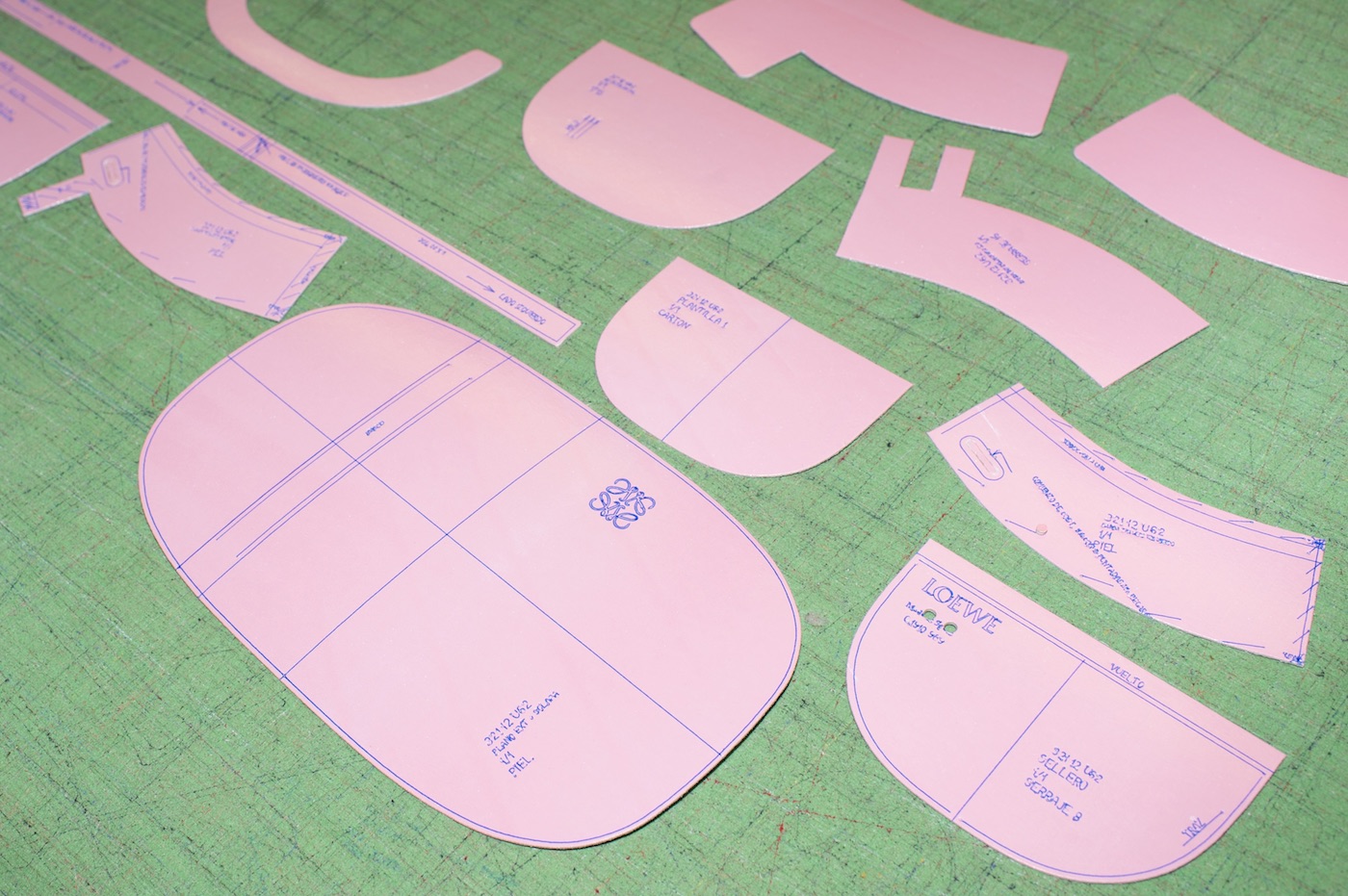

In the Getafe workrooms, the new emblem and logo – in addition to serial numbers and 'Made in Spain' lettering – are heat-stamped onto leathers in a detailed process. Artisan and machine must work in tandem, as the perfect imprint requires a combination of temperature and applied pressure that is specific to each material.

I am told that the best temperature to work soft-grained Nappa Castagneto leather lies between 125 and 130 degrees Celsius, with the machine set for 17mm depth and pressed onto the leather via a lever-system for exactly 20 seconds. Press too hard and the leather will break, too softly and the Loewe logo will be rendered uneven.

The Getafe site is Loewe's midpoint of leather production with a focus on the brand's many bags, from Anderson's refreshed design of the 1975 unlined suede Amazona tote to the Barcelona shoulder-bag with triangular metal buckle. Two models cut and fully assembled in Getafe are recent Anderson creations; both are striking for their complex, Origami-like constructions.

The Puzzle - Anderson's debut Loewe bag - remains the brand's best-seller; it's pattern is also the most detailed to realise and requires hundreds of minute steps. Today, 15 artisans will together finish 27 large black Puzzle bags. Further along, artisans are working on the Hammock; a pioneering design that folds and extends to be worn on the shoulder, across the body or as a square handheld tote.

During our visit, the team is busy crafting Anderson's latest blockbuster creation. Introduced in September last year at Loewe's SS18 womenswear show in Paris, the Gate bag follows the half-moon silhouette of traditional saddle bags. Its name references an ingenious detail: close to the bag's hand-painted edge, a side-latched metallic pin resembles the lock on a set of gates. Form follows function: a decorative knotted belt keeps the front flap securely in place, the belt knot also doubles as a handle.

“I wanted something which had a more sophisticated, relaxed look,” says Anderson. “It needed to be something which had a different functionality, which had this idea of going back to classicism.”

Worn cross-body, the Gate bag is available in three sizes, including a miniature version unveiled this autumn, and in a choice of finishes. Amber and light grey calfskin is matched with a rust brown strap and belt, another model combines leather with a grey, white and red striped felt fabric.

“I believe most people are looking for something that's made well in high quality materials,” Anderson offers. “This is what we do at Loewe. The expert craftsmanship is felt in the design and finish of every bag.”

The team first began work on the new Gate bag over a year before it was presented in Paris. “It happens by sketch, and from the sketch we go through several stages of development,” says Anderson, describing a close collaboration with the Getafe artisans. The Gate bag's easy to wear design belies its intricate construction, which takes more than 320 minutes from cutting to final assembly.

Each Gate bag is made up of 11 panels of leather and three pieces of polished metal hardware; it is the result of a precisely coordinated sequence of production steps. After leathers are stringently checked and its flaws - including scars or mosquito bites - marked with a blue pen, the bag's pattern is drawn onto the material using a laser. All components are then cut by knife, as a laser risks damaging fragile leathers.

In Getafe, a simple colour-coded system means that every bag is crafted using materials transported between workrooms in three boxes: cut leather panels are placed in a blue box while acrylic fabrics used for backing and pieces of metal hardware including zips and buckles are kept in grey boxes.

Before the cut leather pieces can be joined, the material is smoothed along its edges; a machine then coats one side with glue onto which an artisan carefully places the backing. The Gate bag then slowly takes shape on individual trays passed along workbenches. A finishing touch of the Gate bag is its delicately painted edge.

In Getafe, Loewe is taking measures to safeguard its leather expertise, by training the next generation of master artisans. In 2013, the brand opened its Escuela de Maroquinería; the school's curriculum has been drafted in association with the Comunidad of Madrid and the town council of Getafe and teaches all production steps, from leather cutting to final assembly. To date, the school's 13 teachers have instructed 260 budding artisans.

“I think it's incredibly invaluable, it's an asset, it's about generational passing on of information,” says Anderson, describing the pivotal role played by Loewe's Getafe workshop and its assembled team. “Without the master craftsmen, it is very difficult to do what I do so they are a very, very important part of the business.”

Photographer: Lucy Sparks