The secret world of cargo ships

On a modern shipping vessel, what's in the hold is unknown — even to the people moving it

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

You are now subscribed

Your newsletter sign-up was successful

THE BRIDGE OF a modern ship is a shock on first encounter. Although this place is still known as the wheelhouse, the wheel at the helm is not wooden and impressive, but mundane plastic, the kind that would suit a video arcade game. Nearly all else is automated. A bank of screens contains radar, ECDIS — an electronic chart system — and AIS, an automatic identification system that transmits the ship's name, speed and heading, and other details to other ships, port authorities, and well-equipped pirates. There is radio, a gyrocompass and magnetic compass, a tachometer and echo sounder.

Capt. Glenn Wostenholme is often to be found on the bridge. He is here for port approaches and departures but also whenever he can escape paperwork, which is not as often as he would like, now that the role of ship's purser has ceased to exist and all the administration falls on the captain and senior officers. He can be on his computer for four to eight hours a day now. Glenn is the most senior captain in Maersk's container fleet. In older times, he would have been known as commodore and saluted by the raising of flags on courteous passing ships. His talk turns often to earlier times, because he has done enough years to have plenty and because in his four decades on ships, life at sea has changed dramatically. His first ship was a tramp steamer, a freelance vessel that picks up trade where it can, not a liner with a scheduled route like Kendal, his current ship. A taxi, not a bus. It was iron, had derrick cranes on deck to heft cargo about, and was held together by rivets. Rivets! Not like this Korean-made welded ship, only 4 years old.

In front of him the captain sees sea, but mostly he sees boxes. Orange, blue, gray, red. If the captain leaves the wheelhouse to stand on the port or starboard wings — the bridge's two terraces — he will see boxes fore and aft. That is if he sees them at all. For him they are blank, boring. "I am indifferent to them. They're just boxes, you've got to admit." He thinks they have destroyed the soul of a ship and of shipping. This is an old lament. In the middle of the shift from sail to steam, Joseph Conrad complained that "the loading of ships was once a matter of skill, judgment, and knowledge." With the modern steamship, cargo was "dumped into her through six hatchways, with clatter and hurry and racket and heat, in a cloud of steam and a mess of coal-dust."

The Week

Escape your echo chamber. Get the facts behind the news, plus analysis from multiple perspectives.

Sign up for The Week's Free Newsletters

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

Sometime toward the end of the 1960s, when the captain was a young cadet, he saw his first boxes. They were being carried by an American ship that was departing Hong Kong as he was arriving. "I was out on the poop deck and some of the crew said, 'Look! That's a container. That's a thing of the future.'" He didn't pay much attention because cadets didn't pay much attention to things like the creation of globalization. "We were too busy blinking learning stuff." But he listened to the crew, who kept talking about these strange metal things. They said, "That'll never take off." They said, "How are they going to get a truck in that? How will they get steel and timber into it?"

But it did take off. There are at least 20 million containers crossing the world now, quiet blank boxes, thanks to a U.S. businessman named Malcom McLean, who thought people who moved freight would find it easier if they could shift everything in a box, rather than the confusion of general cargo, of barrels and boxes and piles, of each company having its own system. McLean's spark was to call on an engineer, Keith Tantlinger, to create a design that could be seamlessly stacked and locked in place, using twist-locks. This new box could fit trains, trucks, cranes, and ships alike. The "intermodality" made perfect commercial sense, and labor unions hated it. Dockers in particular were furious. McLean claimed his box system reduced labor by two thirds, cutting dockers' workload, salary, and power.

FOR A WHILE they held up the march of the box, as did geography and physics. Ships that carried many boxes would have to be bigger, with deeper draughts. New ports had to be built: New York's maritime wharves — too shallow, too narrow — became useless, and the massive Greater Port of New York–New Jersey was constructed instead. But the rewards of containerization were too great for the dockers to defeat change. Before containers, transport costs ate up to 25 percent of the value of whatever was being shipped. With the extreme efficiencies that intermodality brought, costs were reduced to a pittance. A sweater can now travel 3,000 miles for 2.5 cents; it costs 1 cent to send a can of beer. Shipping a container can cost next to nothing, an invaluable advantage in hard economic times, when there is more supply than demand.

In his junior officer days, the captain was in favor of boxes. They looked like a simpler life. "No more general cargo, all the work involved, no more gear, cranes, derricks, nothing. I thought, 'This has got to be easier.'" His first cellular container ship — one specially built for boxes rather than having to fit them in among derricks and holds — carried only 10 containers. Then there were more and more, and he learned that the boxes gave the gift of speed but they also sucked away his time. You couldn't get any sleep when port hours were so rushed and hurried. Before boxes, he wondered if he had time to go ashore for dinner. Now he wonders if he has time to get a newspaper.

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

He doesn't wonder about the contents of the boxes. They are things full of things, to be moved according to schedule. He doesn't know what's inside them and he doesn't care. I know he drives a Harley-Davidson at home, so I needle him. What if there were a box full of Harleys? "Then there's one full of Harleys. I'm used to the fact that there's no way to get to see them anyway." It would take him days to read the full manifest of all the cargo on Kendal, and anyway, there isn't one on board. A modern container ship is crewed by people who have no idea what they are carrying.

Kendal's crew know only the contents of the refrigerated boxes and the flammable or toxic goods, so that they can put out fires if necessary. We are carrying paint, lacquer, enamel, stain, shellac solutions, varnish, and polish. Somewhere there is liquid flavoring, which is highly flammable and may cause vapors that explode if they meet air. Elsewhere there is some octahydro--tetramethyl-napthalenyl-ethanone, a chemical that can be used in air fresheners or to reduce odor in permed hair. There are 1,828 kilograms of carbamate pesticide, a substance highly toxic to humans, and 180,000 kilograms of metal powder, self-heating. This, I read, "may react violently with water" — on a ship at sea, in containers that are weatherproof, not waterproof.

IN 2004, Al QAIDA reportedly recruited a maritime expert. U.S. security sources revealed in 2010 that the organization had been working out how best to blow up oil tankers. Though why bother with intercontinental missiles or explosives, the urban planning academic Stephen Cohen writes, when you can just ship everything you need in parts and assemble it at the required destination? "Containers...are the poor man's missiles: you no longer have to be a big powerful government to create catastrophe." In 2003, ABC News shipped depleted uranium from Jakarta to Los Angeles in an attempt to expose the weaknesses in port barriers. The stunt didn't go down well at the Department of Homeland Security, whose declared mission is to "stop dangerous things and dangerous people from entering the country," even if those dangerous things are sent by people from a national news channel. In fact, shipping uranium is legal, as long as you declare it. ABC didn't, and no one checked.

Connecting the sea to terrorism has become popular in security studies. Al Qaida certainly understands ships: not only because it rammed the USS Cole with a boat, but because it is thought to own or charter a small fleet. North Korea has its own flag, a fleet of 242 vessels, and the ability to make maritime mischief. Lloyd's List reported in 2012 that 120 vessels had reported GPS malfunctions in seas near North Korea, in an article that suspected the work of a North Korean signals jammer.

A senior government official was asked in 2002 about the threat of maritime terrorism. "This industry is a shadowy underworld," he said. "After 9/11 we suddenly realized how little we understood about commercial shipping." In 2010, Nigerian security forces discovered 240 tons of rockets, mortar shells, and small arms ammunition in 13 containers that had been shipped on the German-owned, French-operated, Marshall Islands–flagged Everest from Bandar Abbas in Iran, despite U.N. sanctions that prohibit Iran from selling arms. The contraband was hidden behind marble slabs and fiberglass. The manifest showed that the recipient was "to order." In short, according to a report, "the ship's owners, operators, and officers had no knowledge or reason for suspicion regarding the container."

Under the layered security scheme managed by the Customs and Border Protection Agency, the perfect U.S.-bound container behaves like this: First the foreign factory that packs it will have joined the Customs-Trade Partnership Against Terrorism and been vetted. Importers and carriers provide information to U.S. Customs, which uses an automated tracking system to identify high-risk containers. The box is shipped to a foreign port that has signed up to the Container Security Initiative, where foreign officials working harmoniously with U.S. Customs identify and scan containers using "non-intrusive inspection equipment and radiation portal monitors," in the words of the Government Accountability Office. While the box is sailing safely onward, updates on its progress are electronically transmitted to the United States. If further doubt remains about the level of risk it poses, upon arrival the container is screened with more nonintrusive inspection equipment and detained or set free.

It is a beautiful vision of a safer global supply chain. A system to scan 100 percent of all U.S.-bound cargo was to be in place by July 2012. Six foreign ports signed on to the 100 percent requirement, but by February 2012 five had dropped out. The process was too expensive and too difficult. In reality, scanning every single U.S.-bound container is an outlandish idea: Customs officials attempting to scan all U.S.-bound containers leaving one Hong Kong terminal managed only 5 percent. The authors of a study commissioned by the EU thought the 100 percent target akin to a trade barrier and undiplomatically said so. The technology to do the scanning isn't yet good enough; the blockages would choke ports. Trade is movement. Trade is sacred. In 2012, the Department of Homeland Security quietly pushed the 100 percent deadline to 2014 and counting.

Excerpted from Ninety Percent of Everything: Inside Shipping, the Invisible Industry That Puts Clothes on Your Back, Gas in Your Car, and Food on Your Plate, by Rose George, published August 2013 by Metropolitan Books, an imprint of Henry Holt and Company, LLC. ©2013 by Rose George. All rights reserved.

-

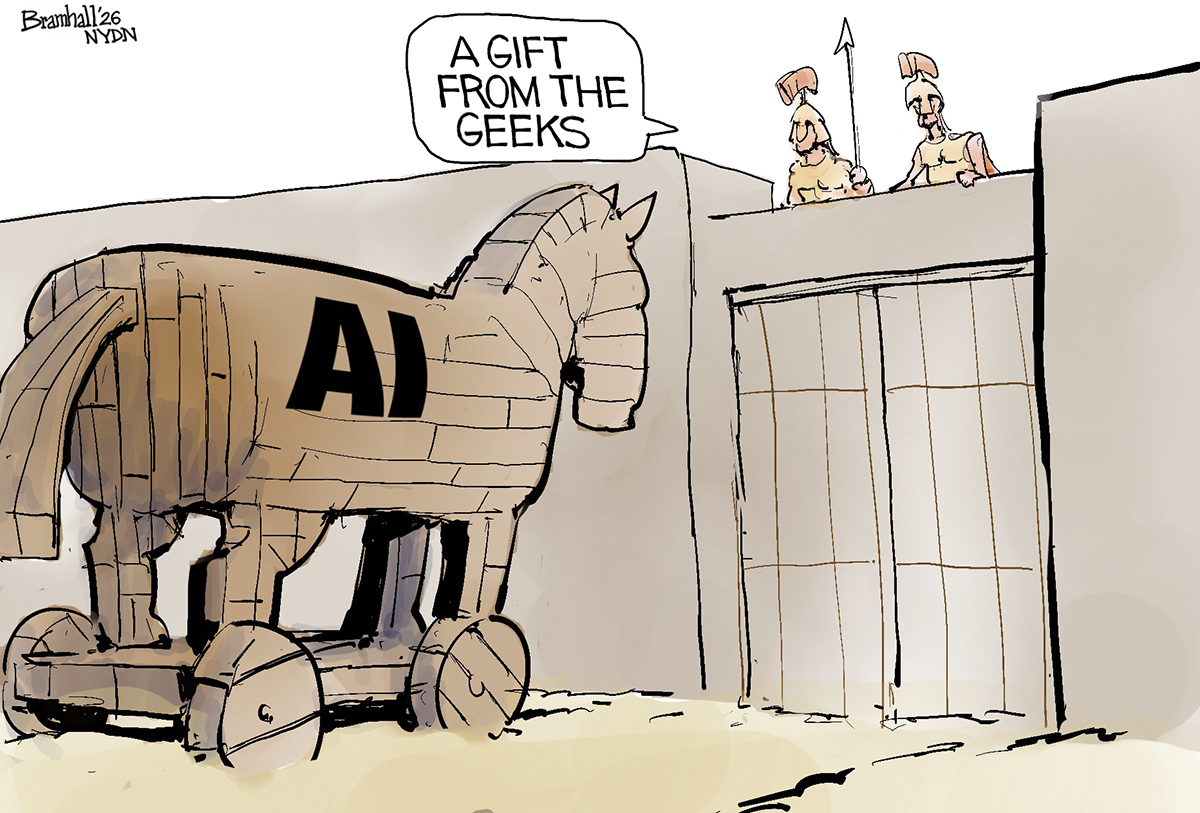

Political cartoons for February 19

Political cartoons for February 19Cartoons Thursday’s political cartoons include a suspicious package, a piece of the cake, and more

-

The Gallivant: style and charm steps from Camber Sands

The Gallivant: style and charm steps from Camber SandsThe Week Recommends Nestled behind the dunes, this luxury hotel is a great place to hunker down and get cosy

-

The President’s Cake: ‘sweet tragedy’ about a little girl on a baking mission in Iraq

The President’s Cake: ‘sweet tragedy’ about a little girl on a baking mission in IraqThe Week Recommends Charming debut from Hasan Hadi is filled with ‘vivid characters’