Will small businesses embrace 3D printing?

Part of our series on the future of Main Street

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

You are now subscribed

Your newsletter sign-up was successful

3D printing can feel almost otherworldly. NASA uses it to make a new ratchet wrench at the International Space Station. Hershey uses it to unveil the candy of the future. Harvard uses it to construct synthetic shark skin. Cirque du Soleil uses it to perfectly fit 18,000 performers' costumes.

But as much as we've heard about 3D printing in recent years, for many Americans, the fundamentals still feel inaccessible, even mythical. And maybe that's why, every year, when we hear this same familiar refrain — 3D printing's time has finally come! — we tend to shrug it off, and maybe even douse it in skepticism.

So take this for what you will: 3D printing's time has finally come. And it may be small businesses that lead the way in its mass adoption.

The Week

Escape your echo chamber. Get the facts behind the news, plus analysis from multiple perspectives.

Sign up for The Week's Free Newsletters

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

(More on the future of Main Street: The booming future of collaborative work environments)

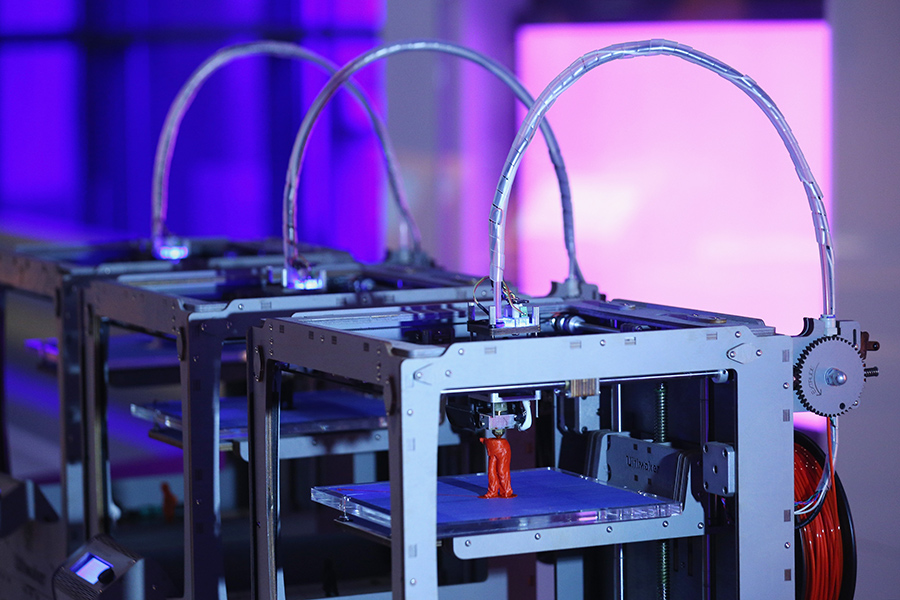

The process, also called additive manufacturing, creates three-dimensional object by horizontally stacking material. Each layer serves as a cross-section of the finished product. A designer must use one of many special software programs to depict the object and create the cross-sectioned slices. The printer then reads each layer, blending them together on top of one another to create one cohesive product.

Shipments of 3D printers are expected to double in 2015, and double again every year after through 2018, according to Gartner, an information technology research firm. An increasingly large number of models of 3D printers are affordable. A quick perusal of the Amazon 3D printing bestsellers shows a lot of models to choose from, many a few thousand dollars or less. They're bound to keep getting even cheaper.

(More on the future of Main Street: The amazing promise of electronic payments)

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

Availability goes beyond just the machinery itself. It's common for major cities to offer classes and training. Some companies offer 3D printer rental programs. Many printing centers, including at least 100 UPS locations and a couple of pioneering Staples print centers, will let you experiment with 3D printers. You can tool around with Adobe Photoshop's expanding assortment of 3D printing tools. You can get support from places like Shapeways, an online marketplace that will print 3D products you design, offer guidance from designers, and sell your work Etsy-style.

Increasingly, the availability and affordability are there. And that's a boon for businesses.

(More on the future of Main Street: How mom-and-pop businesses can thrive in the 21st century)

For example, an eyewear manufacturer in New York told Bloomberg Businessweek that 3D printing his prototypes in house cuts three months off of the eyeglass production cycle. That lets designers try more new things, and faster, instead of feeling pressure to perfect each stab at a new design before a prototype is even produced.

3D printing also allows for customizability and creativity on the customer's behalf. Consider custom jewelers. They were among 3D printing's earliest adopters, and can now quickly and affordably create unique jewelry to a customer's exact specification. It's a great way of establishing an intimate relationship where the customer feels like she shares control over the end product.

Crayon Creatures, a small business out of Barcelona, takes your child's drawing and turns it into a sculpture using Shapeways' service. Akaishi, an established women's footwear in company Japan that ships worldwide, started 3D printing shoes, which they claim has made their product construction faster and more accurate.

As businesses like these continue to find success with 3D printing, more will follow. That's because when enough 3D printed products are out there, customers will come to expect them. It's not that customers will care so much about the exact printing process used, per se, but they will care about the end result, which is bound to be more tailored to their specific needs. Why can't a small toy store custom-build a kid what he wants? Why can't new shoe designs arrive on the shelf with less lead time?

Now, despite its benefits, 3D printing isn't always all that easy for people to pick up. Many small business owners who take the leap are bound to struggle. But as 3D printing continues to grow, it's becoming clear that those who do delve into the technology, whether to prototype, customize, or even just print the occasional spare part for broken equipment, stand to save money and time. That's in addition to impressing customers by throwing off the vibe of being "tech-savvy" and "cutting-edge."

But like most advances in industrial technology, 3D printing is becoming less about the cool factor and more about functionality and efficiency. Expect the more adventurous small businesses to reap the benefits.

Julie Kliegman is a freelance writer based in New York. Her work has appeared in BuzzFeed, Vox, Mental Floss, Paste, the Tampa Bay Times and PolitiFact. Her cats can do somersaults.

-

Film reviews: ‘Send Help’ and ‘Private Life’

Film reviews: ‘Send Help’ and ‘Private Life’Feature An office doormat is stranded alone with her awful boss and a frazzled therapist turns amateur murder investigator

-

Movies to watch in February

Movies to watch in Februarythe week recommends Time travelers, multiverse hoppers and an Iraqi parable highlight this month’s offerings during the depths of winter

-

ICE’s facial scanning is the tip of the surveillance iceberg

ICE’s facial scanning is the tip of the surveillance icebergIN THE SPOTLIGHT Federal troops are increasingly turning to high-tech tracking tools that push the boundaries of personal privacy