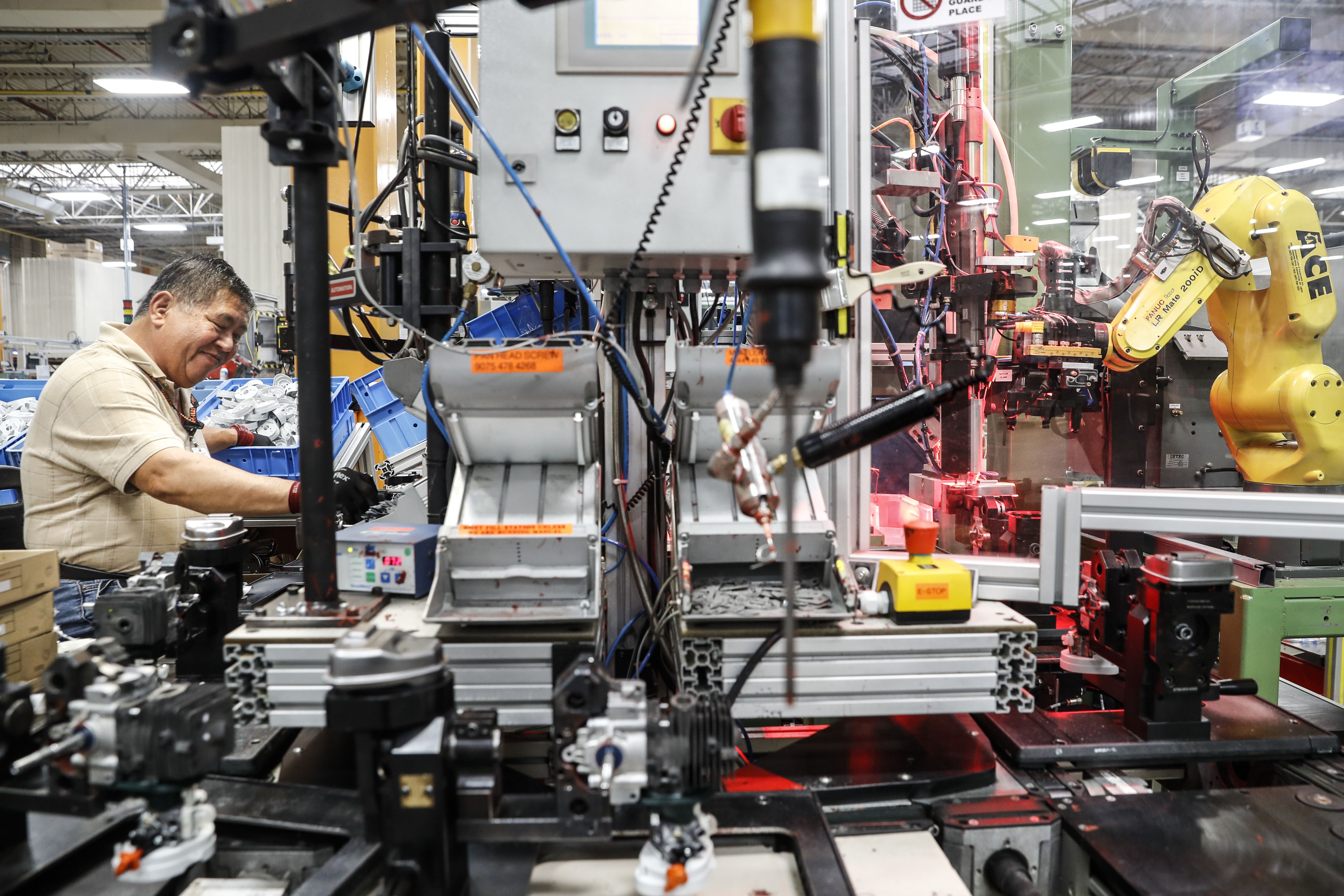

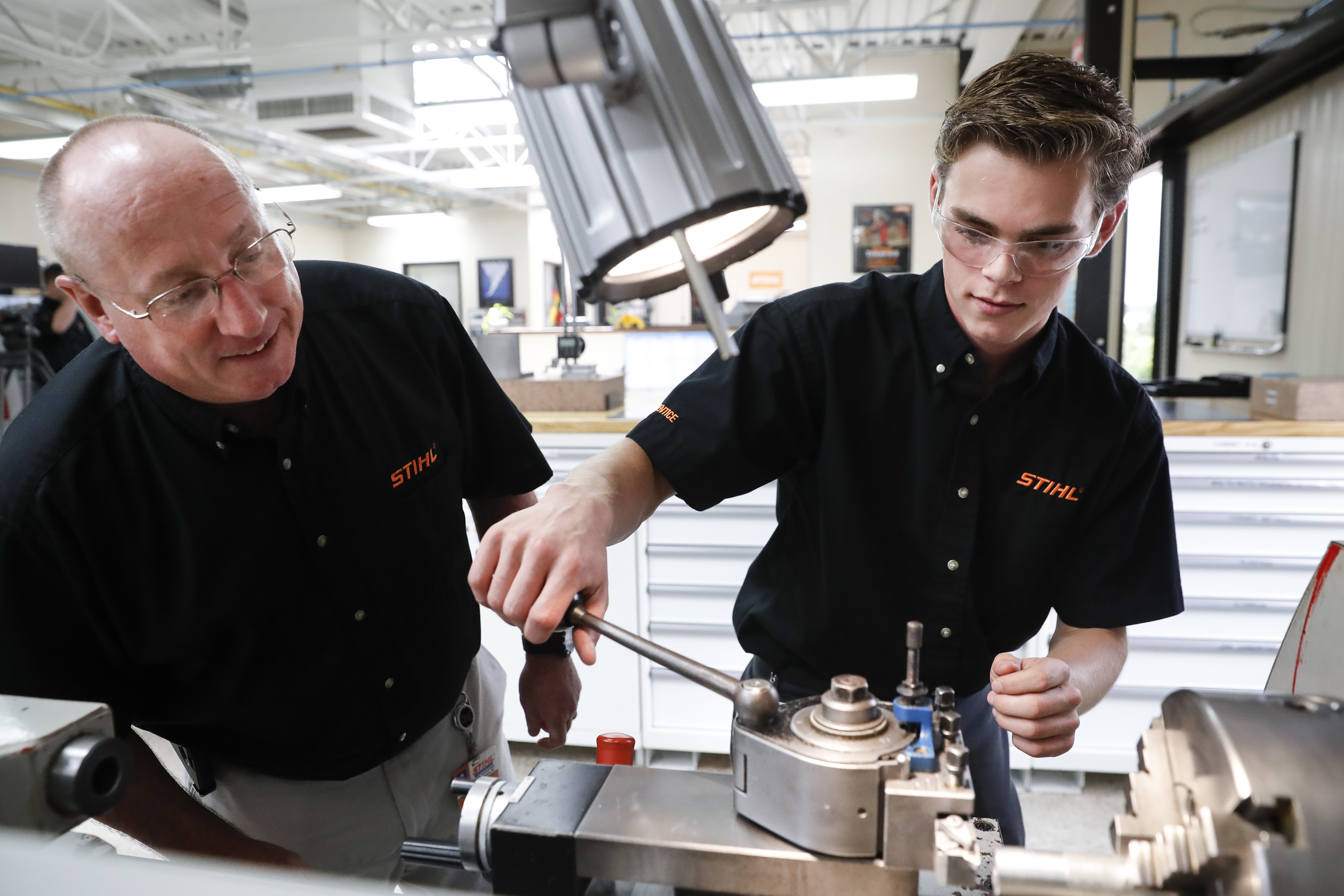

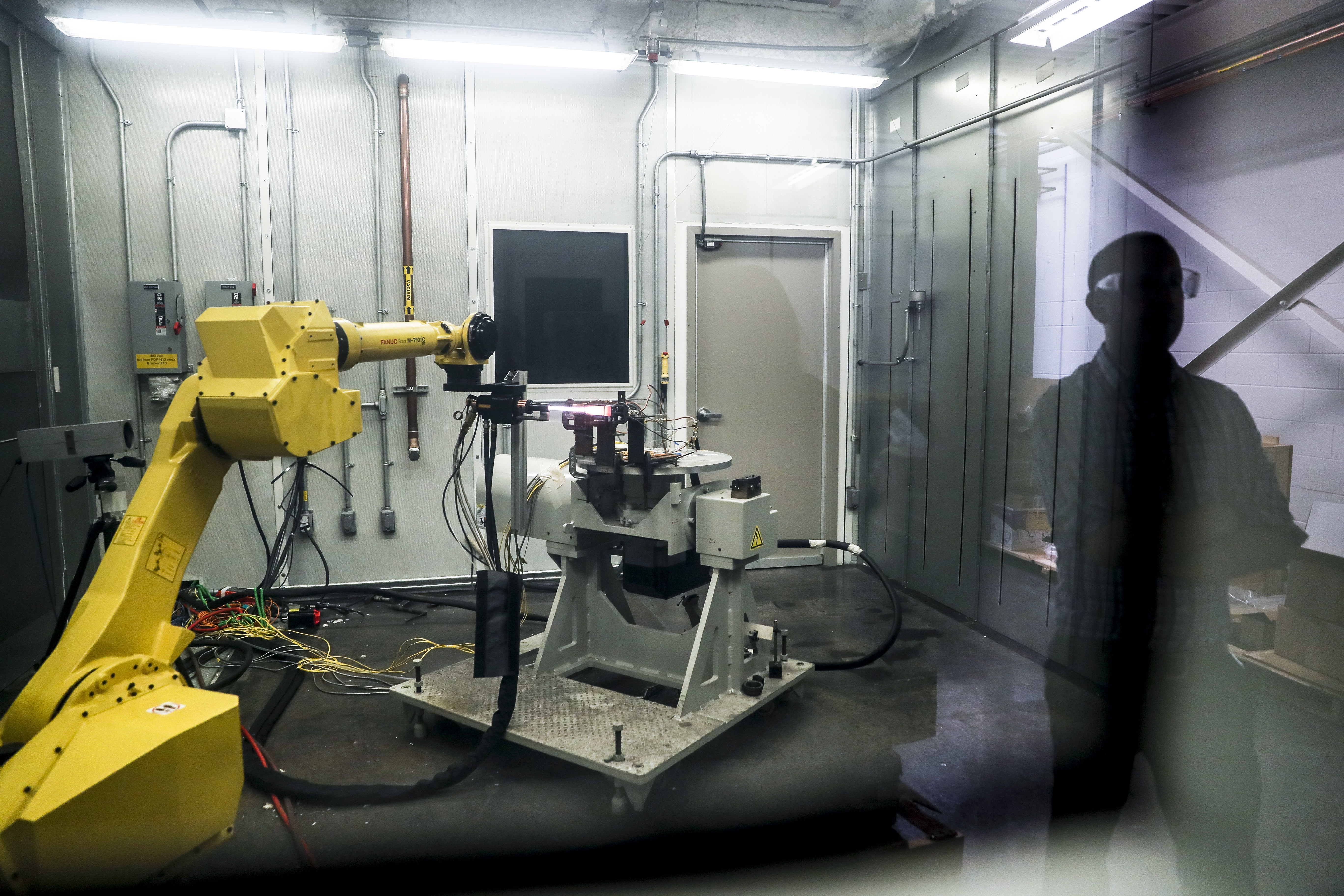

Working with robots

Bustling with sleek machinery and high-powered computers, the factory floor looks nothing like it did decades ago. But human workers are far from obsolete.

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

Kelly Gonsalves is a sex and culture writer exploring love, lust, identity, and feminism. Her work has appeared at Bustle, Cosmopolitan, Marie Claire, and more, and she previously worked as an associate editor for The Week. She's obsessed with badass ladies doing badass things, wellness movements, and very bad rom-coms.

-

Book reviews: ‘American Reich: A Murder in Orange County; Neo-Nazis; and a New Age of Hate’ and ‘Winter: The Story of a Season’

Book reviews: ‘American Reich: A Murder in Orange County; Neo-Nazis; and a New Age of Hate’ and ‘Winter: The Story of a Season’Feature A look at a neo-Nazi murder in California and how winter shaped a Scottish writer

-

28 Years Later: The Bone Temple – ‘a macabre morality tale’

28 Years Later: The Bone Temple – ‘a macabre morality tale’The Week Recommends Ralph Fiennes stars in Nia DaCosta’s ‘exciting’ chapter of the zombie horror

-

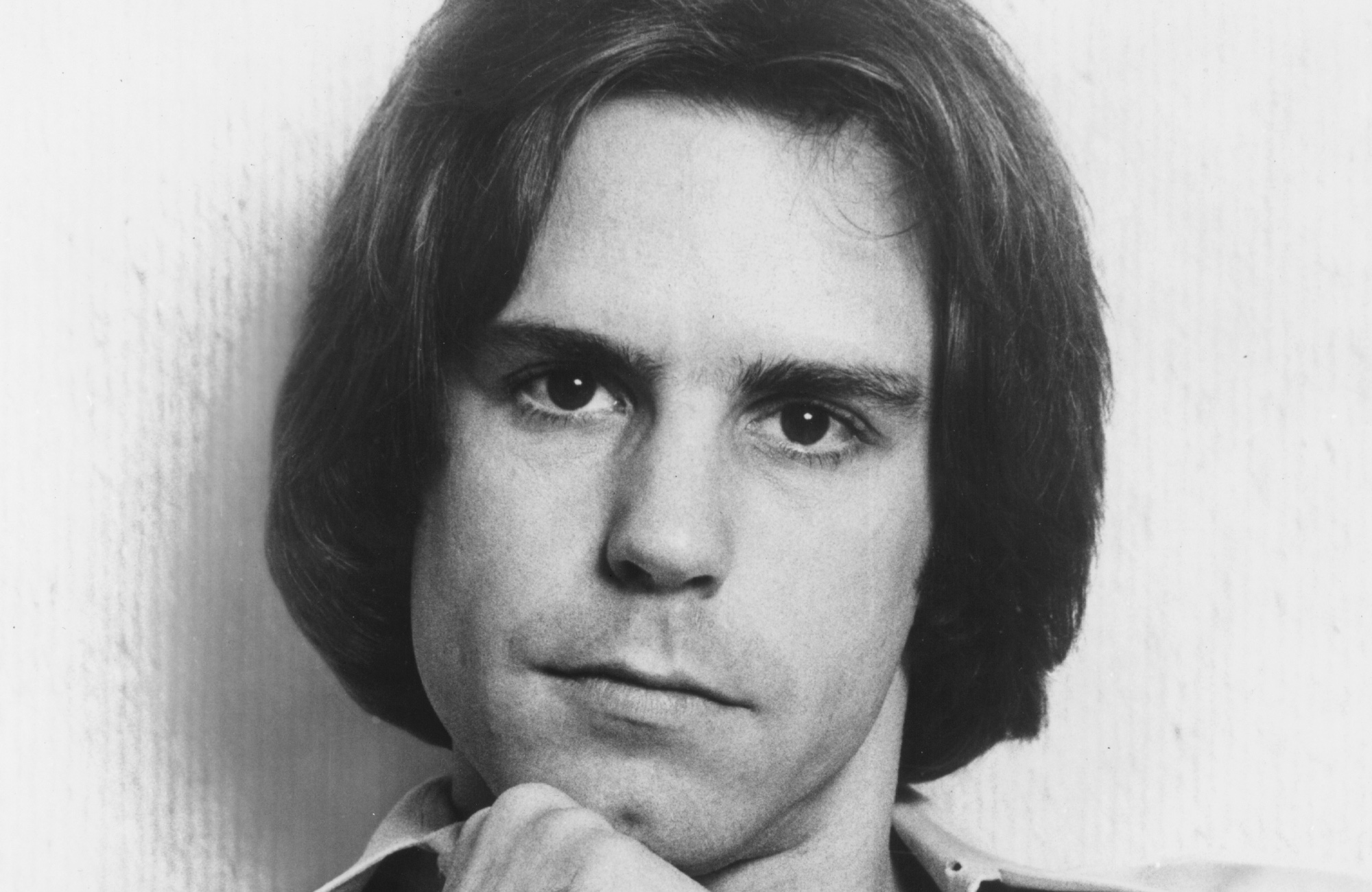

Bob Weir: The Grateful Dead guitarist who kept the hippie flame

Bob Weir: The Grateful Dead guitarist who kept the hippie flameFeature The fan favorite died at 78