La Fabrique du Temps: inside Louis Vuitton's watchmaking manufacture

Why travel, exploration and above all else adventure are at the heart of every Louis Vuitton timepiece

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

You are now subscribed

Your newsletter sign-up was successful

At La Fabrique du Temps Louis Vuitton in Meyrin, a municipality of Geneva, a coiling white staircase with pale wooden steps appears to float between the mezzanine floors of the 3,700 square metres site. Its curving structure, which recalls New York’s Guggenheim, proved a challenge to realise.

"They really had a hard time, but the result was worth it," says Hamdi Chatti, who joined Louis Vuitton in 2010 and today is vice-president of watches and jewellery. "We wanted it floating, because the idea was [for it to look like] a watch hairspring." Viewed from the building’s light-flooded lobby, which is tiled slate grey and rises to a wood-clad ceiling, the modernist staircase resembles the gangway of an ocean liner, had Frank Lloyd Wright turned his hand to maritime designs.

The Parisian luxury powerhouse was first established in 1854 as a maker of specialist trunks. This included the Trianon, an ingenious, canvas-coated construction with a flat top to allow for easy stacking. A taste for exploration continues to underpin the brand’s creations: earlier this year, Nicolas Ghesquière, Artistic Director of Women’s collections, chose Japan’s Miho Museum – a 50-minute drive from Kyoto – to stage his Cruise 2018 show, and Kim Jones looked to remote islands and Hong Kong as inspiration for his Spring 2018 menswear designs.

The Week

Escape your echo chamber. Get the facts behind the news, plus analysis from multiple perspectives.

Sign up for The Week's Free Newsletters

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

Travel also informs the designs and functions of Louis Vuitton timepieces. Tambour, the brand’s 2002 debut watch collection, interpreted the shape of traditional Japanese taiko drums with a round case that widens towards its base, a concave bezel, and one-letter-per-hour 'Louis Vuitton' engraving on the case band. An instant design classic, the Tambour has inspired many variations, such as the 41.5mm Tambour Brun GMT with its cognac-coloured face – an homage to LV’s Monogram canvas, launched in 1896. “The heritage is the base, and you cannot build without a base,” explains Chatti. "The thing is, you need to see heritage with a new eye, with no fear, no ghosts."

Earlier this year, this approach gave rise to the Tambour Horizon (pictured top). Developed in collaboration with Google and Qualcomm Technologies Inc, the first Louis Vuitton smartwatch incorporates a departure tracker – My Flight – as well as a geolocation function that syncs the brand’s city guides to your destination, allowing you to discover the best restaurants, attractions and places of interest while exploring your surroundings.

"The starting point was very strong; it was the Tambour shape," says Chatti, reflecting upon LV’s journey since the launch of its first timepiece. "The big step was that we decided to do everything by ourselves, from the design and prototyping to the manufacturing." Chatti, whose CV includes top-tier roles at Piaget and Harry Winston, masterminded the creation of today’s manufacture.

In July 2011, Louis Vuitton purchased a Geneva-based specialist movement workshop set up by watchmakers Michel Navas and Enrico Barbasini. The following March, the brand added a second independent atelier to its fold when it purchased expert dial-maker Léman Cadrans. To house its growing cadre of highly skilled artisans in one building, Louis Vuitton relocated in October 2014 from its original La Chaux-de-Fonds manufacture to the current site in Meyrin.

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

La Fabrique du Temps Louis Vuitton employs 65 artisans, including eight dial makers. "It’s their place," says Chatti, describing a laboratory-like set-up where specialists in different fields collaborate freely, both in and outside the open-plan workshops. "We have a beautiful cafeteria. The coffee is for free, and the lunch is not very expensive, so watchmakers, designers, marketing and salespeople, everybody has lunch here. That’s important as it allows for discussions outside meetings."

Its location places La Fabrique du Temps Louis Vuitton at the heart of Swiss watchmaking; Chopard and Patek Philippe also have workshops in Meyrin. “It’s watch land,” says Chatti, quite undeterred by the competition. "You need to fight for it, and to fight you need to be in the ring. You don’t go outside the ring, otherwise it's not a real fight."

It may be a relative newcomer, but La Fabrique du Temps has proven a worthy opponent. In February 2016, just 16 months after opening its new manufacture, LV announced that a skeleton tourbillon movement conceived and assembled in Meyrin had been awarded the Poinçon de Genève, a mark of superior watchmaking dating back to 1886, backed by the Canton of Geneva and granted to timepieces adhering to a stringent set of criteria. Once crafted in Meyrin, each watch undergoes two weeks of testing before the Poinçon de Genève emblem is added to the face of the flying tourbillon.

La Fabrique du Temps Louis Vuitton adds the flair of a Parisian luxury brand to the meticulous operations of an expert Swiss watch manufacture. Chatti’s office is furnished with iconic designs such as Warren Platner’s 1966 curved steel rod Arm Chair, an off-white futon originally built for one of the brand’s fashion shows, and a miniature LV trunk. Form follows function inside the window-lined workrooms where carefully labelled drawers contain the many tools of the watchmaker’s trade, some of which are so specialised to individual tasks that they are created in-house.

In the technical department on the ground floor, where two engineers solve the puzzle of translating new designs into blueprints of movements and cases, computer screens flicker with the second Meyrin-conceived and manufactured timepiece to be awarded the Poinçon de Genève. Released in time to celebrate the 15th anniversary since Louis Vuitton first launched fine watches, the Tambour Moon Flying Tourbillon took almost two years to conceive. Using 3D CAD software, cases and movements are mapped in detail. From this plan, a resin prototype is produced, layer by layer, using a 3D printer. The supersize rendering of tiny components is testament to the many hours’ work and advance planning required for this initial prototype to become the finished timepiece.

To obtain the Poinçon de Genève, all components must be finished by a trained watchmaker; just one watch amounts to two months’ work. The Tambour Moon Flying Tourbillon is a feat of material mastery, too: its skeleton construction uses a one-way mirror so as not to reflect the wearer’s skin; also, the bridge and platinum case back can be monogrammed to specification. While retaining the signature features of the original drum-inspired watch, the September 2017-issued Tambour Moon collection premiered a slight change: viewed as a cross section, the new case is shaped like a crescent, explaining the watch's lunar-inspired name.

A sense of mystery and intrigue is at the heart of every LV timepiece. When Chatti first returned to Meyrin from Paris with a sketch of the Escale Worldtime Minute Repeater, his artisans deemed the watch’s dial too difficult to produce because of its intricate design, which displays the local time in 24 time zones alongside colourful geometric squares inspired by the brand’s trunks. Then one dial specialist revealed that he corrected minuscule imperfections on topographically printed dials by hand to save time. Chatti encouraged his colleague to apply his skills to the Escale Worldtime. The technique, which takes 40 hours per model, involves applying tiny droplets of acrylic paint – there are 38 types, mixed in-house – to each of the dial’s small cubes with a bristle brush. Paints are applied one tone at a time; to achieve the signature curved surface, each cube requires several layers.

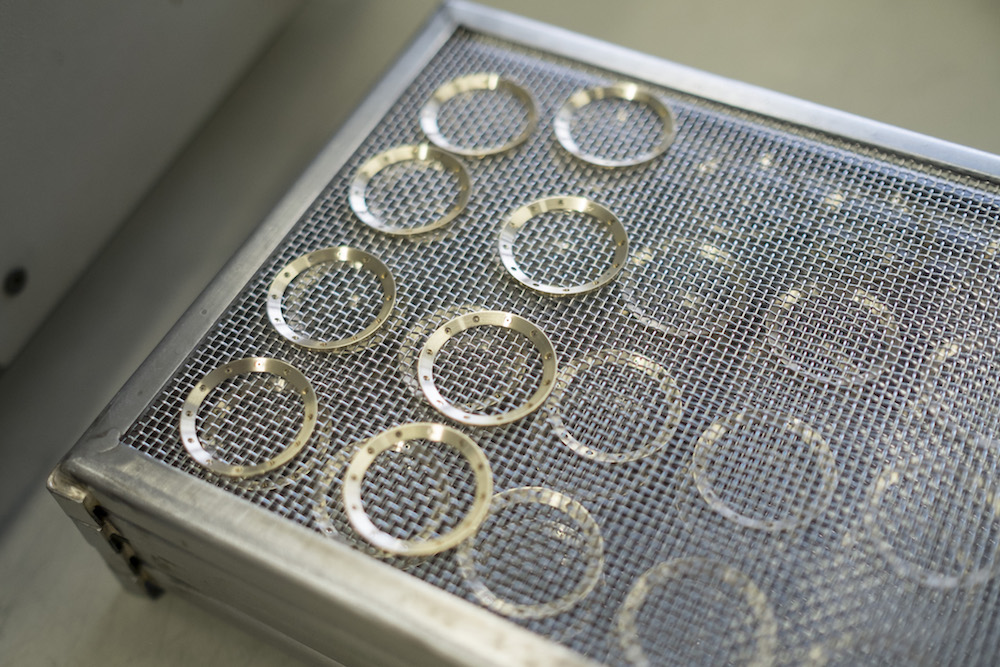

Miniature painting is but one practice perfected at La Fabrique du Temps Louis Vuitton to create exceptional dials: an entire level of the manufacture is dedicated to this, and there are 20 to 50 operations required, depending on the model. Dials are brushed to achieve a number of finishes including sunray, satin and the striped Côtes de Genève motifs. There’s also the Dentelle de Monogram, a delicate LV speciality inspired by French lacework and created by filing, drilling and carving Polynesian mother-of-pearl into the four-point stars and flowers of the brand’s monogram.

Leading the specialised complications workshop are Navas and Barbasini, the original duo brought in by the French marque in 2012. The pair still assemble the first runs of all newly devised complications. The first to be completed in Meyrin was the Spin Time, which displays the time via rotating steel cubes whose shape takes after LV’s legendary Damier checkerboard pattern, first released in 1888.

Lace-like dials, cubes painted with micro-brushes and playful display functions may sound like artistry meant for contemplation rather than everyday wear, but Chatti is adamant that Louis Vuitton watches are above all functional, just like the brand’s trunks, which were originally conceived for discerning travellers embarking on real-life adventures via unwieldy 19th-century modes of transport. Indeed, a choice of easily interchangeable straps for models including the Tambour Moon GMT 41.5 and Tambour Horizon allow for all-terrain wear, and even the Tambour Minute Repeater, a complication regarded as the most intricate and fragile of all mechanisms, is water-resistant to 30 metres. It is also the only minute repeater watch to display the local time abroad but chime the wearer’s home time, proving that exploration and pragmatism is at the heart of this business. "Crack open the safe!" says Chatti. "You need to wear your watch. You need to enjoy it every day. That’s a key element of how we design our watches."

Photographer: Simon Martin

-

The environmental cost of GLP-1s

The environmental cost of GLP-1sThe explainer Producing the drugs is a dirty process

-

Greenland’s capital becomes ground zero for the country’s diplomatic straits

Greenland’s capital becomes ground zero for the country’s diplomatic straitsIN THE SPOTLIGHT A flurry of new consular activity in Nuuk shows how important Greenland has become to Europeans’ anxiety about American imperialism

-

‘This is something that happens all too often’

‘This is something that happens all too often’Instant Opinion Opinion, comment and editorials of the day