4 ways the Juicero went so terribly wrong

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

You are now subscribed

Your newsletter sign-up was successful

You have probably already heard the tale of the very expensive, useless juicer that does nothing that you can't do just as well, or perhaps faster, with your own two hands. "Juicero" quickly became the laughingstock of the whole internet and perhaps deservedly: The device, which went on the market for $699 but has now reduced its price to $399, is a hilarious example of Silicon Valley at its silliest and most absurd.

Despite the flop, Bolt venture capital firm founder Ben Einstein dissembled the Juicero and found that the machine is actually an "incredibly complicated piece of engineering." Here's how, precisely, it went so wrong and got so pricey:

1. The Juicero made things way, way more complicated than they needed to be. The door-locking mechanism, for example, consisted of more than two dozen parts. "Of the hundreds of consumer products I've taken apart over the years, this is easily among the top 5 percent on the complexity scale," Einstein noted.

The Week

Escape your echo chamber. Get the facts behind the news, plus analysis from multiple perspectives.

Sign up for The Week's Free Newsletters

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

2. At least Juicero wasn't lying when it said it was good at squeezing. "Juicero's juicer really does appear to be capable of putting out the kind of strong, controlled force the company promised it would use to squeeze the juice out of fruits and vegetables," The Verge writes. But: "On the other hand, Juicero put a ton of money and effort into something that could have been accomplished much cheaper if it had been willing to accept a less precise squeeze — say, something similar to what's accomplished by hand."

3. And about those costs … "Most hardware startups avoid machined parts as much as possible because the cost doesn't decline much as production volumes increase," Einstein wrote. Juicero has eight.

4. That's not to mention the plastics. "This one uses an expensive process called overmolding with a special kind of injection molding press that takes two separate hard plastic parts and molds them together with a softer, rubber-like polymer to make a single 'part.'" One spunky red doodad Einstein displays probably costs between $4 and $6. And that's just for one tiny piece.

Read Einstein's entire breakdown (with pictures and helpful arrows) here.

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

Jeva Lange was the executive editor at TheWeek.com. She formerly served as The Week's deputy editor and culture critic. She is also a contributor to Screen Slate, and her writing has appeared in The New York Daily News, The Awl, Vice, and Gothamist, among other publications. Jeva lives in New York City. Follow her on Twitter.

-

The Olympic timekeepers keeping the Games on track

The Olympic timekeepers keeping the Games on trackUnder the Radar Swiss watchmaking giant Omega has been at the finish line of every Olympic Games for nearly 100 years

-

Will increasing tensions with Iran boil over into war?

Will increasing tensions with Iran boil over into war?Today’s Big Question President Donald Trump has recently been threatening the country

-

Corruption: The spy sheikh and the president

Corruption: The spy sheikh and the presidentFeature Trump is at the center of another scandal

-

TikTok secures deal to remain in US

TikTok secures deal to remain in USSpeed Read ByteDance will form a US version of the popular video-sharing platform

-

Unemployment rate ticks up amid fall job losses

Unemployment rate ticks up amid fall job lossesSpeed Read Data released by the Commerce Department indicates ‘one of the weakest American labor markets in years’

-

US mints final penny after 232-year run

US mints final penny after 232-year runSpeed Read Production of the one-cent coin has ended

-

Warner Bros. explores sale amid Paramount bids

Warner Bros. explores sale amid Paramount bidsSpeed Read The media giant, home to HBO and DC Studios, has received interest from multiple buying parties

-

Gold tops $4K per ounce, signaling financial unease

Gold tops $4K per ounce, signaling financial uneaseSpeed Read Investors are worried about President Donald Trump’s trade war

-

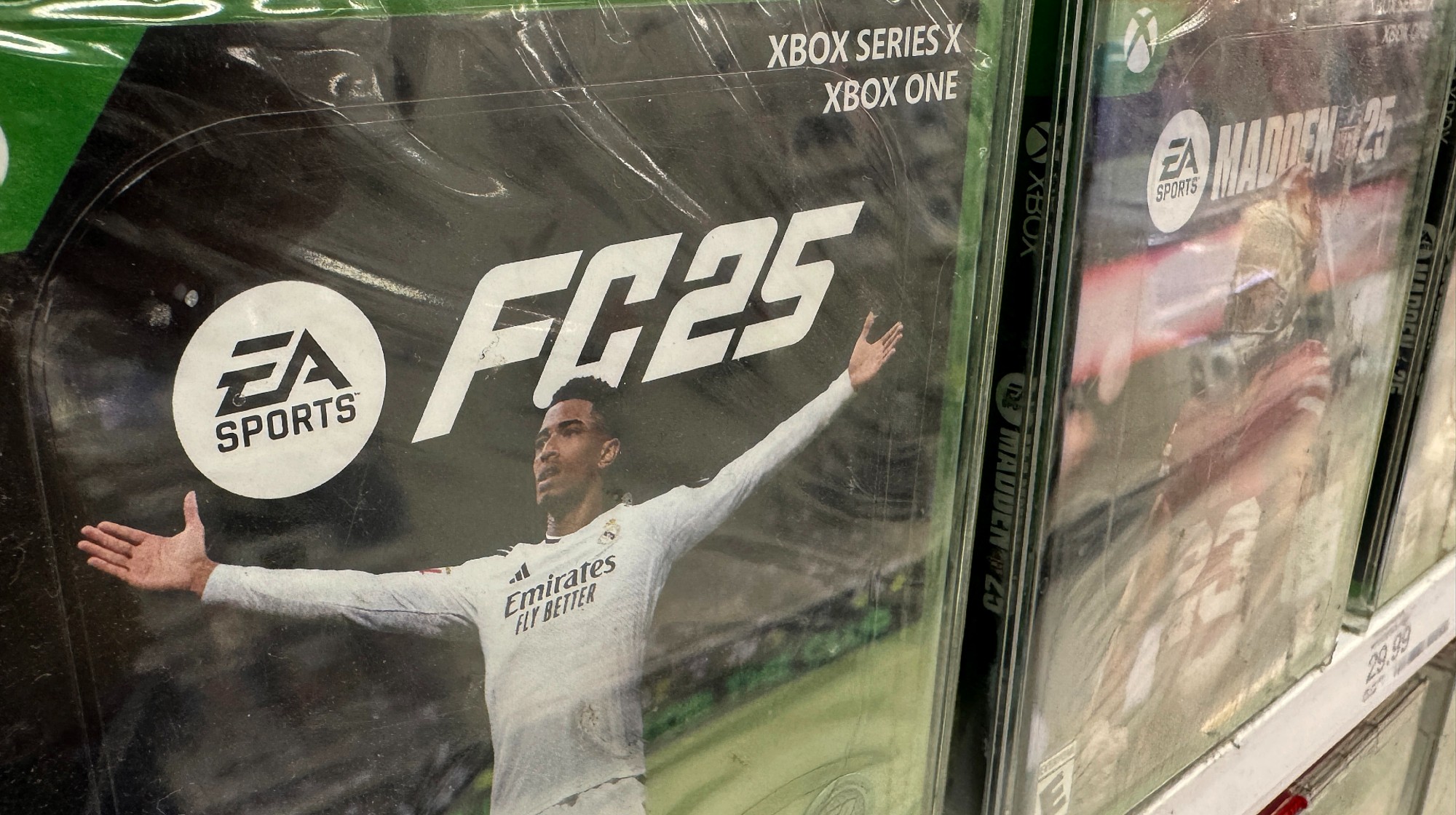

Electronic Arts to go private in record $55B deal

Electronic Arts to go private in record $55B dealspeed read The video game giant is behind ‘The Sims’ and ‘Madden NFL’

-

New York court tosses Trump's $500M fraud fine

New York court tosses Trump's $500M fraud fineSpeed Read A divided appeals court threw out a hefty penalty against President Trump for fraudulently inflating his wealth

-

Trump said to seek government stake in Intel

Trump said to seek government stake in IntelSpeed Read The president and Intel CEO Lip-Bu Tan reportedly discussed the proposal at a recent meeting