London Craft Week 2017: Aston Martin's design secrets

The luxury carmaker reveals its traditional design process during London Craft Week

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

You are now subscribed

Your newsletter sign-up was successful

London Craft Week 2017 kicked off with a host of brands and artists opening hidden workshops across the city to offer a glimpse into their design techniques.

Leading the way was Aston Martin, which allowed a select few the chance to discover what goes into creating some of its most iconic cars at the company's boutique in Mayfair.

Julian Nunn, Aston Martin's lead exterior designer, could be found sketching the design of Aston's most recent car, the DB11, while revealing some of the vehicle's hidden styling features.

The Week

Escape your echo chamber. Get the facts behind the news, plus analysis from multiple perspectives.

Sign up for The Week's Free Newsletters

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

The DB11 has a host of aerodynamic aids hidden in the design features or underneath the bodywork, he told The Week Portfolio, when we went to visit the event. For example, at the front of the car, Aston's signature side-strake helps disperse the "build-up of air pressure in the front wheel arch if you're driving fast".

He added: "What you'll find is it gets rid of the central pressure in the front wheel arch, which comes down the side of the body and helps the car drive, turn and corner."

Moving further back, air moving over the top of the car is channelled underneath the rearmost section of the DB11, removing the need of a spoiler.

These wings "spoil the shape of a car", he said, but through its racing programme, Aston found a way to "separate the belt line and the floating cant rail", allowing air to pass through the body without compromising the car's looks.

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

"It gives us different finishes" on the roof, added Nunn, so buyers can choose from a selection of colours and materials for a more personalised look.

Aston Martin's clay modelling team also showed attendees why the hands-on practice is still used by the carmaker.

John Cummings, head of clay modelling at Aston, told us the benefit of a physical model over computer animated designs (CAD) is that clay structures are "very quick to change".

He added: "To change a model, all I need to do is go over to the oven, heat it up and you end up with a physical model."

If the designer requests an alteration, the clay model can be tweaked within "a couple of minutes", while CAD models require a longer period of time and a team of computer engineers to alter.

Cummins's work ranges from small-scale replicas to full-size production mock-ups, he said. Larger models, used for motor shows and design, can take around two weeks to build with a team of three to four people.

Aston Martin may be a small company compared to the likes of Jaguar Land Rover and other European brands, but it prides itself on mixing traditional design techniques with forward-thinking styling to set itself apart from the competition.

London Craft Week runs until Sunday 7 May.

-

Colbert, CBS spar over FCC and Talarico interview

Colbert, CBS spar over FCC and Talarico interviewSpeed Read The late night host said CBS pulled his interview with Democratic Texas state representative James Talarico over new FCC rules about political interviews

-

The Week contest: AI bellyaching

The Week contest: AI bellyachingPuzzles and Quizzes

-

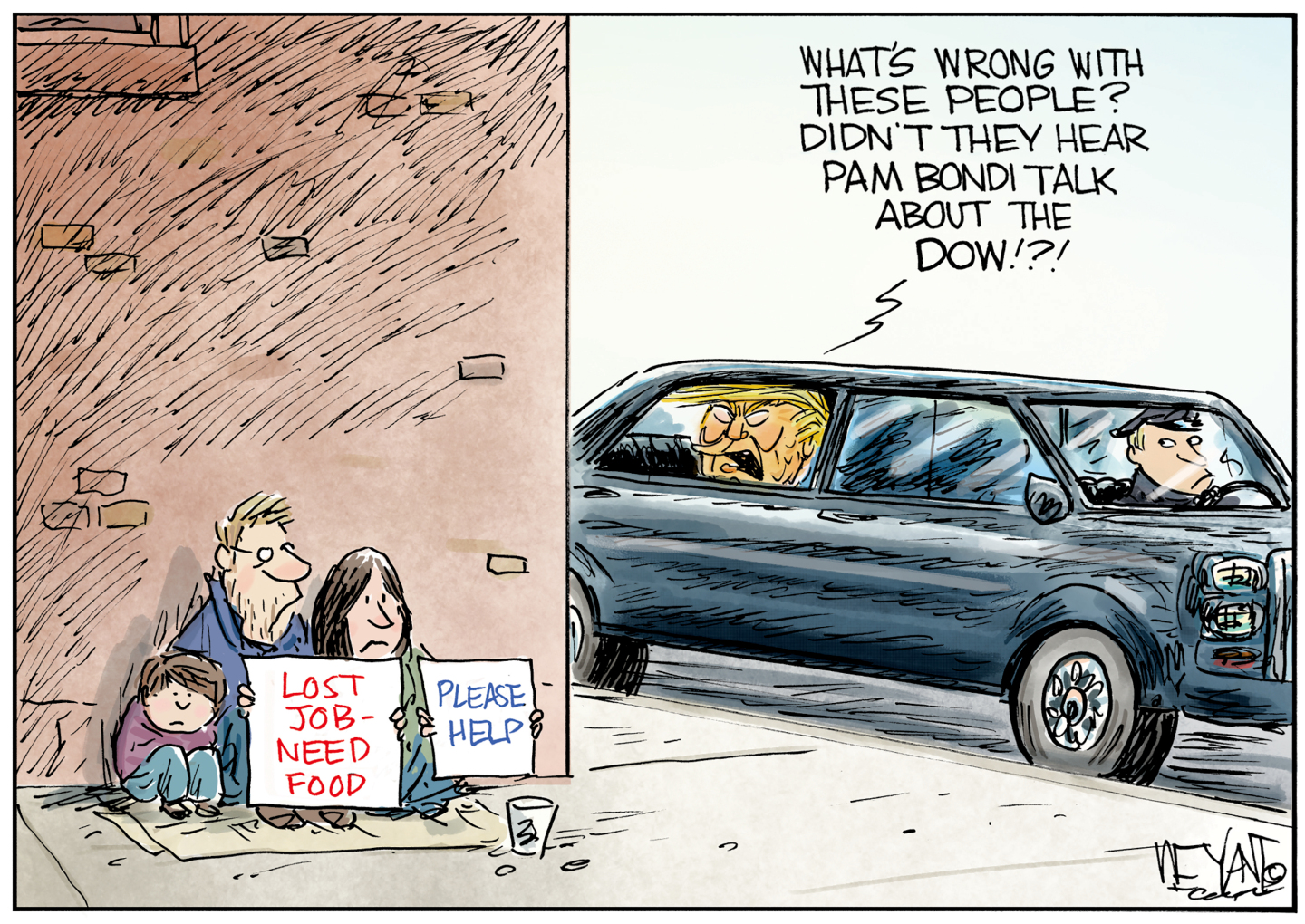

Political cartoons for February 18

Political cartoons for February 18Cartoons Wednesday’s political cartoons include the DOW, human replacement, and more

-

Aston Martin Vantage Roadster: 'a rare treat indeed'

Aston Martin Vantage Roadster: 'a rare treat indeed'The Week Recommends The Roadster version of Aston Martin's new Vantage coupé makes even 'the most mundane journey feel special'

-

Aston Martin DBX707 review: the fastest production SUV on sale

Aston Martin DBX707 review: the fastest production SUV on salefeature A ‘true leviathan’, the 707 is a very different type of DBX

-

Aston Martin Vantage Roadster: ‘a hot rod with manners’

Aston Martin Vantage Roadster: ‘a hot rod with manners’Speed Read Majestic convertible has a top speed of 190mph

-

AMR-C01: Aston Martin unveils £57,500 luxury racing simulator

AMR-C01: Aston Martin unveils £57,500 luxury racing simulatorSpeed Read Could this be the ultimate addition to your home games room?

-

Troubled Aston Martin loses over £100m in 2019

Troubled Aston Martin loses over £100m in 2019In Depth The luxury car builder continues to plunge deeper into the red, and its £500 million bailout boost has been tarnished by coronavirus fears

-

Aston Martin has launched a luxury chopper for Bond villains

Aston Martin has launched a luxury chopper for Bond villainsSpeed Read If you’ve a few million to spare, the man at Aston Martin wants to talk to you

-

Aston Martin heads off road with the all-new DBX

Aston Martin heads off road with the all-new DBXSpeed Read Aston Martin, Britain’s supercar maker, is branching out into SUVs. Its new DBX looks a winner.

-

Goodwood Revival 2019 review: racing through the ages

Goodwood Revival 2019 review: racing through the agesThe Week Recommends The annual event is home to ‘the world’s most expensive motor race’ but the off-track action steals the show