Introducing the iPhone 6, made in China by a robot

Apple will reportedly be the very first customer of Foxconn's latest robots

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

You are now subscribed

Your newsletter sign-up was successful

The worst kept secret of Apple and its Taiwanese manufacturer Foxconn isn't their poor labor conditions. It isn't even the fact that they use robots to help bring together all the pieces that make up an iPhone. It's that their robots are now performing more and more human-like functions.

In the past, it's always been people that put the finishing touches on the popular devices. Well, that's all about to change.

Foxconn parent company Hon Hai is set to deploy an army of 10,000 assembly-line robots to help meet the demands of producing the highly anticipated iPhone 6. Hon Hai CEO Terry Gou revealed in a recent shareholder meeting that Apple would be the very first customer of Foxconn's latest robots.

The Week

Escape your echo chamber. Get the facts behind the news, plus analysis from multiple perspectives.

Sign up for The Week's Free Newsletters

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

"Robots are going to enhance and speed up the manufacturing process," said Tim Bajarin, CEO of market research firm Creative Strategies. "The really big issue here is that the demand for the iPhone continues to grow. It's grown every quarter since it came out."

From a business standpoint, it makes sense. "When you are dealing with creating millions of smart phones per month, efficiency is critical," said Bajarin in an interview. "Robotics gives you that level of efficiency, which in the end, is very important for the bottom line."

Throughout its various factories in China, Foxconn employs more than 1.2 million workers. They have reportedly hired an additional 100,000 workers in China — yes, human ones, to work alongside the robots.

"I wouldn't be surprised if sometime in the next five years, robots will even take care of the final touches," said Bajarin.

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

Some analysts see this trend toward robotics transforming labor markets globally. Marshall Brain, founder of How Stuff Works and author of Robotic Nation, says the push towards automation is happening much faster than people realize. "Within a couple of decades," said Brain in an interview, "there won't be a single job that robots can't do better than humans."

But phasing out human labor altogether is easier said than done. Foxconn's original commitment to implement one million robots by 2014 has hit its fair share of roadblocks. By 2011, the company had reportedly rolled out 10,000 robots to work in their Jincheng, Shanxi Province factory, but several production line workers complained that the machines were incapable of doing the most basic human tasks.

Known as "Foxbots," the machines were part of a larger effort to help offset increasing labor costs. Hon Hai's 2013 financial report stated, in part, "To remain cost competitive, we have been continuously controlling manufacturing overhead to attain better operating leverage and improving efficiency and yield rate through automation using robot arms and industrial engineering methods like production cell management."

The shift to automation will undoubtedly lead to substantial productivity gains for companies, but as that happens, jobs will be increasingly at risk.

"We have been dealing with robots on manufacturing lines for almost 50 years, said Bajarin. "The fact that they are getting faster, smarter, and able to do more intricate tasks is a concern in the sense — as it was 50 years ago — that it impacts job creation."

Larry Summers, former U.S. Treasury secretary during the Clinton Administration and former head of Obama's National Economic Council, predicts technology will have a profound effect on the average employee. "We are seeing less and less opportunity for what average people — people lacking in certain skills — are going to be able to do," said Summers in May at the Conference on Inclusive Capitalism.

"It is not true that innovation always makes more employment…There is nothing in the logic of the market or human experience to suggest that it must necessarily be so that there will be jobs for all at acceptable wages, no matter how technology evolves."

Job-killing technology is hardly new. From 2000 to 2010, over a million secretary jobs were eliminated from the U.S. labor market as answering machines and computers replaced them at lower costs. But robots could put the trend into overdrive. Now, people may not have to worry about their job going to someone overseas, but to something right down the street.

"Right now, there's a big process of automating all of the warehouses in the United States. It used to be you had people running around picking stuff out of warehouses and putting them in warehouses," said Brain in an interview. "That whole process is going to be pretty much completely automated within the next couple of years. No one really pays attention to it because warehouses aren't in places we normally go. But that's going to happen."

Producing some of Apple's products is already an almost completely automated system. In 2013, the company began producing its Mac Pro at the Flextronics Americas factory in Northwest Austin. They may get to engrave "Made in USA" on their products, but some argue it does more harm than good. "It's located in Texas, which makes everybody feel good," said Brain, "but it's not providing any jobs."

It makes geography, and the debate about outsourcing jobs, almost entirely insignificant. "If robots are taking more and more of the manufacturing jobs," said Bajarin, "it actually doesn't matter whether it's here or in Asia."

Brain predicts the trend is heading in this direction globally — and beyond low-skill factory work.

Indeed, Foxconn isn't just in the business of putting labels on chicken soup cans. They recently manufactured a robot in Japan that might serve as more of a companion at home than as a coworker on the assembly line. Designed by French robotics company Aldebaran, it's a semi-humanoid robot named "Pepper," who is reportedly equipped with some social skills, too. In a twist worthy of the movie She, where a man falls in love with a computer generated "friend," Pepper has an "emotion engine" that can reportedly understand human emotion, interpret it, and react accordingly.

Japanese telecom giant SoftBank commissioned the construction of Pepper, and plans to sell what they refer to as "the newest member of the SoftBank crew" in Japan next February. The price tag for your newest 1.2 meter tall little friend? Just under $2,000.

SoftBank was built on the philosophy of 'Information Revolution – Happiness for everyone.' "To realize our vision," said SoftBank CEO Masayoshi Son in a statement, "We have made a new entry into the robot business with the aim of developing affectionate robots that make people smile."

Of course, many doubt workers will be smiling when those robots take their jobs.

More from The Fiscal Times...

-

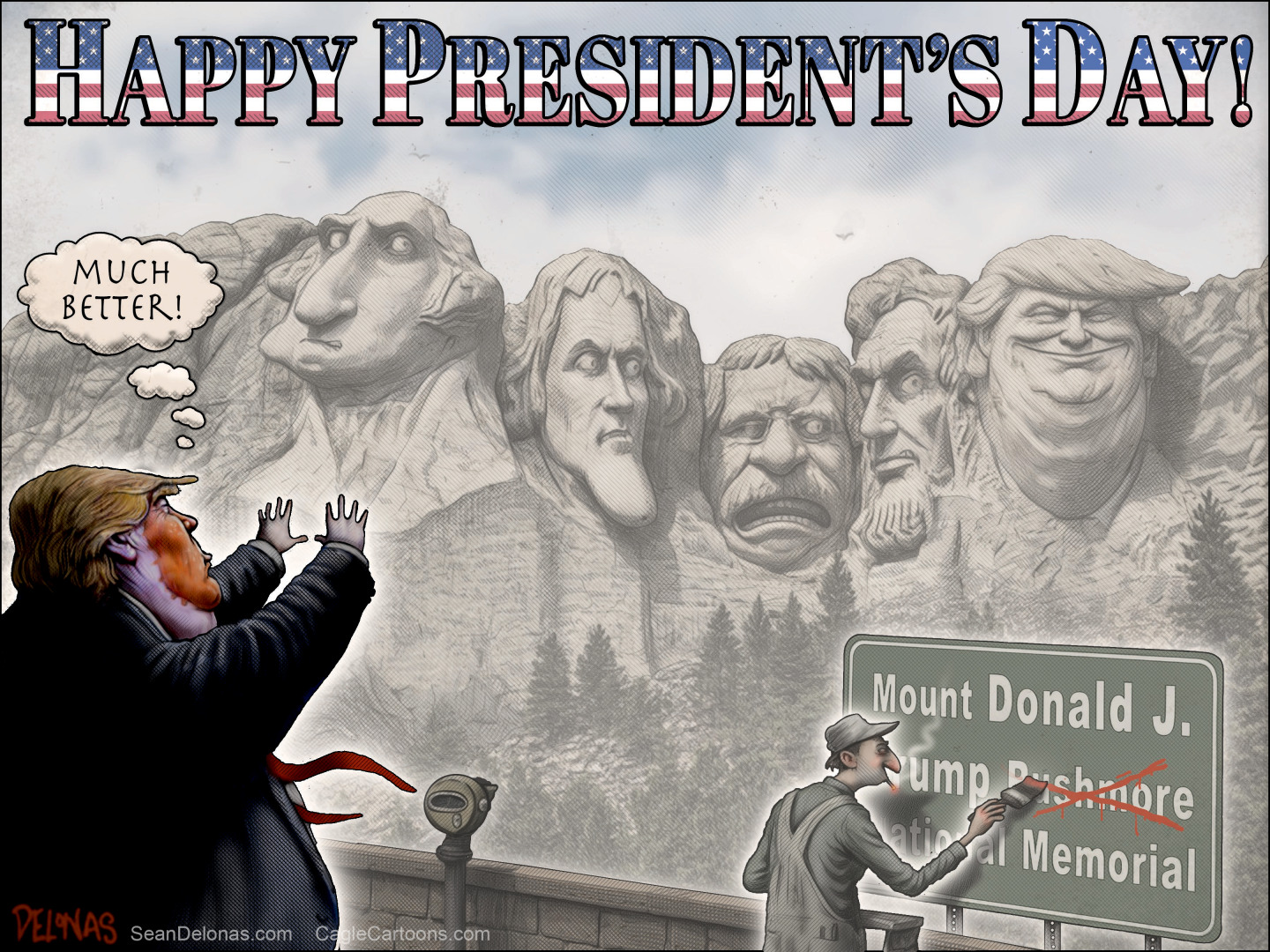

Political cartoons for February 16

Political cartoons for February 16Cartoons Monday’s political cartoons include President's Day, a valentine from the Epstein files, and more

-

Regent Hong Kong: a tranquil haven with a prime waterfront spot

Regent Hong Kong: a tranquil haven with a prime waterfront spotThe Week Recommends The trendy hotel recently underwent an extensive two-year revamp

-

The problem with diagnosing profound autism

The problem with diagnosing profound autismThe Explainer Experts are reconsidering the idea of autism as a spectrum, which could impact diagnoses and policy making for the condition