The key to elegance: inside Jaeger-LeCoultre

To understand the timeless appeal of the luxury watchmaker, you need to explore the details

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

You are now subscribed

Your newsletter sign-up was successful

The workshop of Swiss watchmaker Jaeger-LeCoultre, located in the scenic Jura region, is a place of wonderful contradictions. For a start, it is one of the largest makers of timepieces in the Vallée de Joux – also home to Audemars Piguet, Patek Philippe, Breguet and Blancpain – with more than 1,200 employees, and yet the work undertaken by many of these J-LC experts centres on the microscopic.

One could justifiably argue that all fine watchmakers are masters of precision, as they often work with hand-finished parts no larger than specks of dust; the difference here is that since 2016 Jaeger-LeCoultre has united all prestige crafts under one roof, from miniature painting undertaken by artists working with single-bristle brushes to meticulous gem-setting to the mind-boggling art of watch assembly in the complications and grand complications workshop.

Each line of work is so painstakingly precise that these are less métiers than tests of human endurance, requiring seemingly preternatural focus; artistry along with a high aptitude for science and engineering. This brings us back to the initial contradiction: while there may be more than 1,200 employees at this ultra-modern factory, some are so specialised that no other artisan can replicate their work.

The Week

Escape your echo chamber. Get the facts behind the news, plus analysis from multiple perspectives.

Sign up for The Week's Free Newsletters

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

From our morning news briefing to a weekly Good News Newsletter, get the best of The Week delivered directly to your inbox.

“I take the time I need to take,” says Aline, a petite woman in her forties, who is alone in making the watchmaker’s intricate balance springs - some flat, others domed or indeed spherical, all only a few millimetres wide. “Like everyone, I get sick sometimes and I have to take time off, but here we don’t finish things to complete a quota, we deliver things according to when they can be finished.” Another contraction, then: a ‘maker of time’ that doesn’t watch the clock when it comes to production.

The tiny coiled springs that Aline so expertly winds are an essential part of the watch engine; they ping back into shape, allowing the balance wheel to oscillate at a regular rate, which moves the watch gears and thus the watch hands forward. Thinner than a hair’s breadth, these intricately made parts are really micro-sculptures: each tier of the coil must be manipulated by Aline to match the last rotation in studied equidistance.

The J-LC Sphérotourbillon, a multi-axis tourbillon mechanism that serves to negate the effects of gravity, looks like a tiny three-dimensional heart beating within the watch dial and draws its inspiration from Earth’s own rotating axis; it includes a cylindrical balance spring that takes Aline a whole day to produce.

If you consider that the Duomètre Sphérotourbillon watch has a calibre with 460 components – 105 of these belong to the Sphérotourbillon cage itself, including the spring – you get a sense of how much work goes into each and every part of a J-LC high complication, and that’s before you factor in the dial decorations and finishings.

A free daily email with the biggest news stories of the day – and the best features from TheWeek.com

Balance springs may not be sexy per se, but they give rise to extraordinary watch complications when made to this standard.

A case in point is the Master Grande Tradition Gyrotourbillon Westminster Perpétuel, which the company revealed at this year’s SIHH watch fair in Geneva. The complex name of the timepiece betokens the extraordinary engineering housed within its framework.

This includes a multi-axis gyrotourbillon (as its name suggests, this complication acts like a gyroscope) that is equipped with a revolutionary spherical balance spring and appears to magically orbit a droplet-like universe on the dial; a perpetual calendar (no need to change time or date until 2100), and a minute repeater mechanism – considered by many as the acme of watchmaking – that replicates the chimes of Big Ben.

The watch is a marvel to behold, but of course it’s incredibly exclusive, with only 18 pieces in existence of two watch models, each calibre taking three months to assemble.

Such innovations require a huge investment of time and resources, but these daring advances in engineering are contrasted with an artisanal prowess that is steeped in tradition – some surprisingly anachronistic, but all the more charming for it. For example, the sprinkle-like pallets on each side of the lever, which help the escapement wheel rotate, are made of synthetic rubies that are produced and assembled at the manufacture, making J-LC one of the only watchmakers in Switzerland to still perform this dual practice.

Even more surprising is the fact that these minute cuboid rubies are fixed in place with natural shellac, an amber coloured resin secreted by lac bugs found in parts of Asia.This organic substance, noted for its glossy and adhesive qualities and processed into flakes, was first used in Europe at the end of the 16th century as a furniture varnish, although in India and China lac dye has its roots in medicine and crafts reaching as far back as 3,000 years.

The use of this organic matter in J-LC watches is indicative of the manufacture’s investment in a purity of craftsmanship, which comes to life at the Métiers Rares, a department dedicated to hand-executed high-prestige crafts, encompassing gem-setting, enamelling, engraving and remarkable guillochage work.

Guillochage – the decorative process of creating delicate, repetitive patterns on dials and small watch parts – is performed by hand at Jaeger-LeCoultre, using antique lathes or engine-turning machines from the early 20th century. This is unusual given the futuristic design of the manufacture, which resembles a giant maze-like laboratory, and is also a point of difference from many other luxury watchmakers in the region, which tend to use contemporary versions of these instruments.

“Modern machines would not allow us to achieve such delicate and arresting results,” explains Stéphane Belmont, director of heritage and rare pieces for Jaeger-LeCoultre.

What’s more, it takes nine months to know how to use one of the lathes even at a basic level. Presently, just one expert artisan – a chic lady in her early fifties named Murielle, who has worked for J-LC for more than 20 years – has custody of these machines, because of her guilloché experience.

Murielle can engrave 180 perfectly spaced diagonal lines onto a tiny disc the size of a 50p piece (she must also go over each line three times), creating a sunburst guilloché dial that reflects the light in spectacular fashion. Incredibly, she performs this eye-wateringly precise task with such ease that she has her own nonchalant style, spinning the wheel of the machine with either her hand or her foot, or both at the same time, as if she’s bareboating along a smooth canal. “It’s not a special technique, it’s just the way I like to work,” she reveals with a knowing smile.

Jaeger-LeCoultre’s iconic Reverso watches, known for their square Art Deco-inspired swivel cases, are personalised with engraved initials in this same Métiers Rares unit. Moreover, it is here that exclusive Reversos become portable masterpieces: expert craftspeople reproduce famous paintings by artists such as Van Gogh, Seurat and Alphonse Mucha in miniature on the backs of the ‘flippable’ Reverso watch cases, as well as on the round dials of special high-complication timepieces.

It’s not just a question of painstakingly accurate painting either: coloured enamel must be fired layer-by-layer in special high-temperature ovens that are set to 800°C. This is known as Grand Feu enamelling, a method that requires much patience, as, depending on the variety of tones used, dials can be fired as many as 22 times. Each colour intensifies in the heat, which makes remaining faithful to the original composition a very delicate operation indeed.

The level of detail on these Lilliputian masterworks is astounding; the greatest visual paradox being the J-LC rendition of Katsushika Hokusai’s The Great Wave, which is the size of a postage stamp. And yet, every speck of frothy exuberance has been skilfully sealed in time thanks to inordinate amounts of nimble brushwork and careful firing. Look closely and you can even make out the burst of tiny droplets bouncing off the crest of the wave, just as you can on the original artwork.

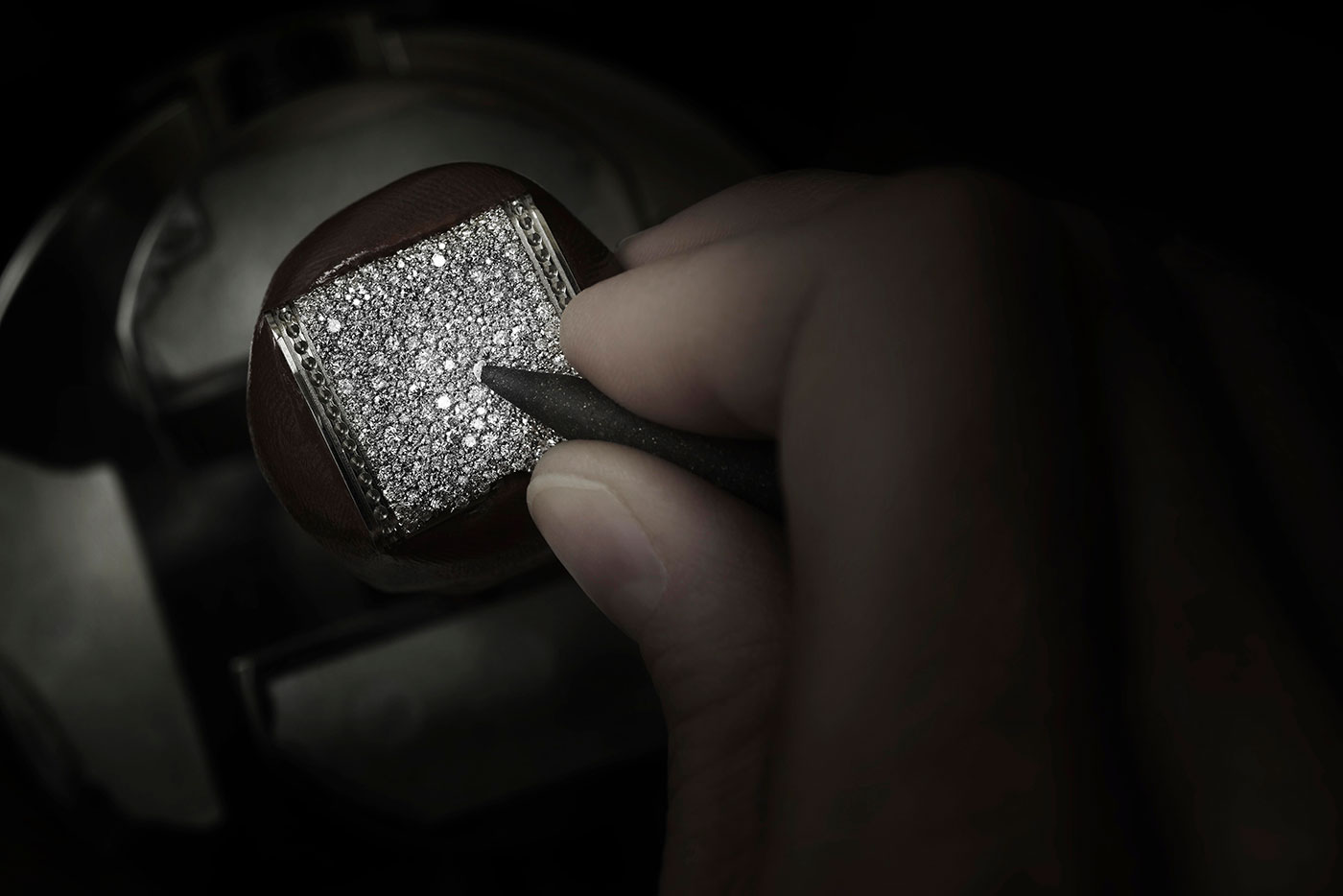

Gem-setters work in this unique and light-filled space, too, where they bring to life dials and bracelets with techniques not often seen in fine watchmaking. For example, a pair of new Dazzling Rendez-Vous Night & Day High Jewellery timepieces for women, released this January, have two rings of diamonds set around the bezel: an inner circumference of traditional grain-set diamonds contoured by larger diamonds in a prong setting, where metal claws hold the stones in place, allowing for more light-striking potential and thus more twinkle.

The process of cutting, setting and placing the diamonds one by one by pressing these claws over each stone, then smoothly beading the excess metal so that every jewel is perfectly secure, requires extreme precision and perfect craftsmanship; each ‘double-wreathed’ diamond Rendez-Vous bezel takes a gem-setter two days to complete.

Requiring even more labour-intensive work are the maison’s snow-set and chaotic-set designs, which, as the name suggests, are high-jewellery timepieces saturated in diamonds, all cut to varying sizes to fit the given shape, be it the back of a Reverso case or a floral-shaped dial. The chaotic-set design is so-called because the cobbled gems are also set at an angle, and both methods lend these haute joaillerie watches a striking supernova-like effect – a surface bursting with sparkle. It takes a gem-setter no less than one hour to secure just four gems on a snow-set piece, which underscores the level of patience and skill needed to construct these diamond jigsaws.

“We have a long history of high-jewellery pieces that set a standard of excellence starting with the 101,” explains Stefan Richi, who manages the Métiers Rares atelier. The 101 refers to Jaeger-LeCoultre’s family of delicate diamond bracelet watches powered by a micro calibre (named the 101 and first introduced in 1929), which remains the world’s smallest mechanical watch movement. The Queen famously wore a 101 bracelet watch on her Coronation Day in 1953, andFrance’s reine d’élégance, Catherine Deneuve, is also a fan.

If there is one horological achievement that truly exemplifies the enigma of Jaeger-LeCoultre – the je ne sais quoi that harnesses the nuances of methodical engineering and time-honoured tradition – it’s the Atmos clock, another icon in watchmaking history, first introduced by J-LC in 1928.

The singularity of Atmos’ construction is its energy hub, which isn’t driven by a power source or by a pendulum but uses an airtight capsule containing a mixture of gases that expand and contract with changing temperatures. As such, the instrument requires no winding, since even a 1°C change in temperature is sufficient to ‘charge’ the clock for two days.

Over the decades, the Atmos has appeared in a variety of guises, from the ornamental – such as those presented in Art Nouveau gilded-wood casings – to the industrial (see Luigi Colani’s 1973 rhodium-plated steel version, noted for its minimalist engine-like design.)

More recently, in 2013, Hermès produced a perforated helmet-inspired case for the Atmos, while prodigious designer Marc Newson has conceived a variety of striking models that are cast entirely from glass and look like majestic giant ice cubes.

By far the most classic iteration is the elegant gold framed glass-caged Atmos, an enduring style, that, like Newson’s model, best showcases the mysterious workings of this ever-intriguing time capsule. Rare models of the iconic clock are kept for posterity at Jaeger-LeCoultre’s archive department, which is located at the heart of the manufacture, in the original home and workshop of Antoine LeCoultre, established in 1833. How pleased he would be to know that authenticity, innovation and forward thinking have stayed close to their original source, both in spirit and in design.

As of May 2019, the Swiss watchmaker will present a unique 'Care Program' which offers an 8-year International Limited Warranty across all clocks and watches - a first in the world of high prestige timepieces.

Should you already be lucky enough to own a JC-L timepiece under warranty you will be eligible for a warranty extension upon online registration to this program at jaeger-lecoultre.com/services

Alexandra Zagalsky is a London-based journalist specialising in luxury, art and travel. She began her career working on a cultural guide for English-speaking expats in Paris, where her first major break was an interview with Lionel Poilâne, the late baker of Saint-Germain-des-Prés famed for his signature sourdough loaves. Returning to London in her early 20s, she went on to write for not only The Week but also The Art Newspaper’s Art of Luxury supplement, The Telegraph and The Times, as well as art and design platforms including 1stDibs’ Introspective Magazine and the magazines of the V&A, Sotheby’s and Christie’s. She studied fine art and art history at Goldsmiths, University of London and continues to explore travel journalism through the lens of art, craftsmanship and culture.